2025 | Professional

Decision Support System for Optimized Wood Preservation

Entrant Company

Shanghai Zhenzhi Wood Industry Co., Ltd.-Zhao Wenxin

Category

Conceptual Design - Technology

Client's Name

Country / Region

The Decision Support System for Optimized Wood Preservation is an intelligent software platform that integrates advanced materials science models with decision-making algorithms to achieve full-process parameter optimization and quality closed-loop control in wood preservative treatment production lines. It ensures that construction wood maintains superior and durable preservative performance under diverse environmental conditions.

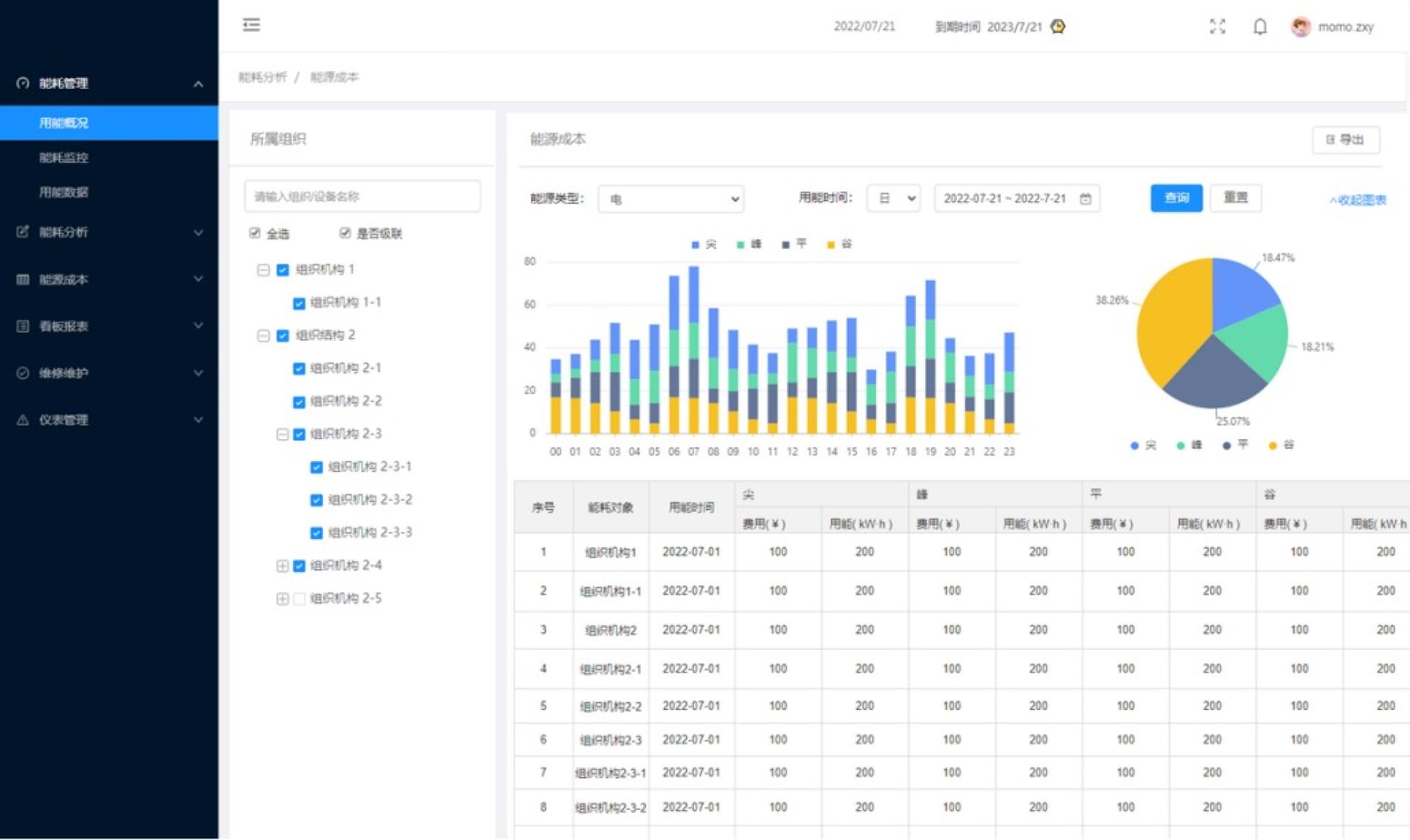

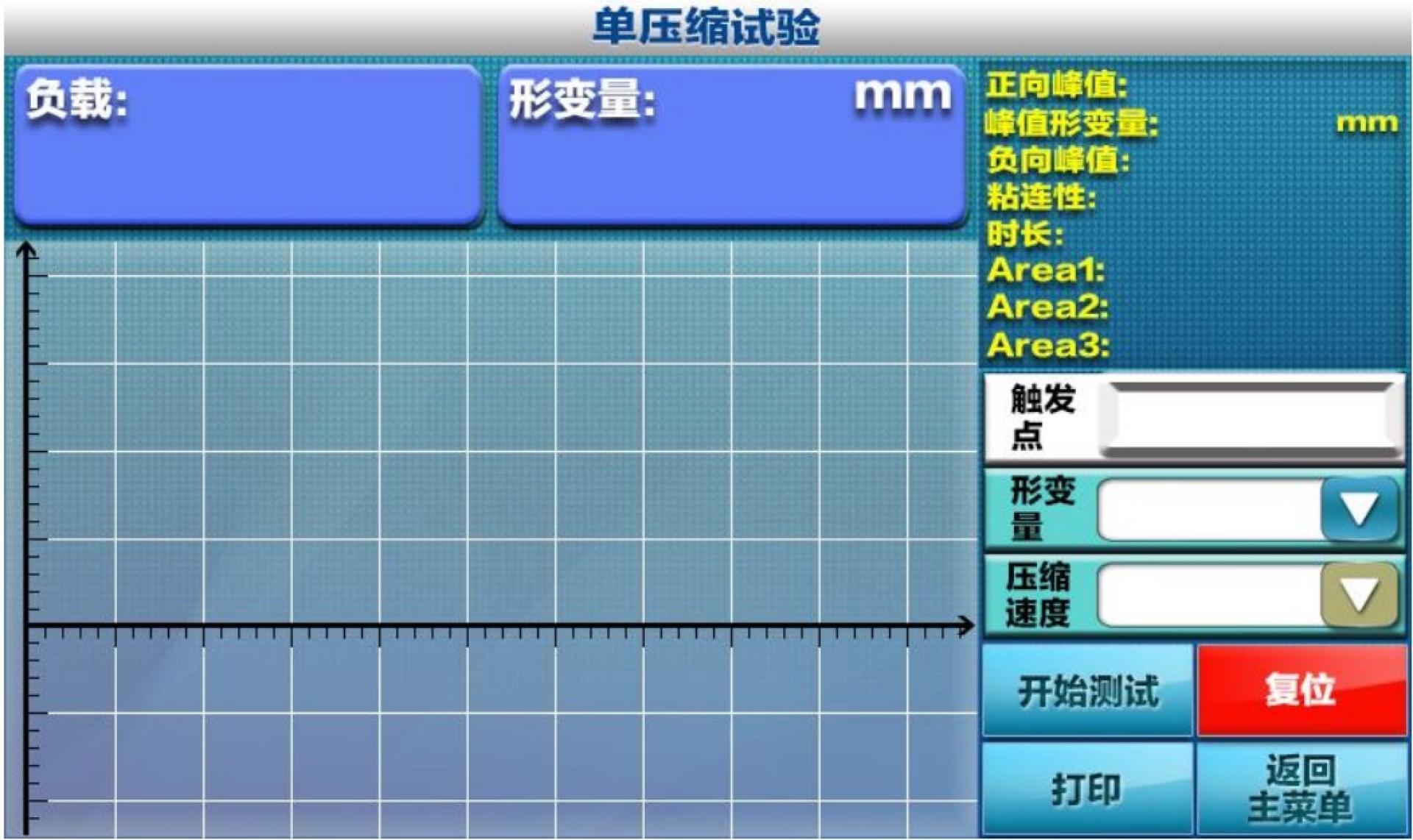

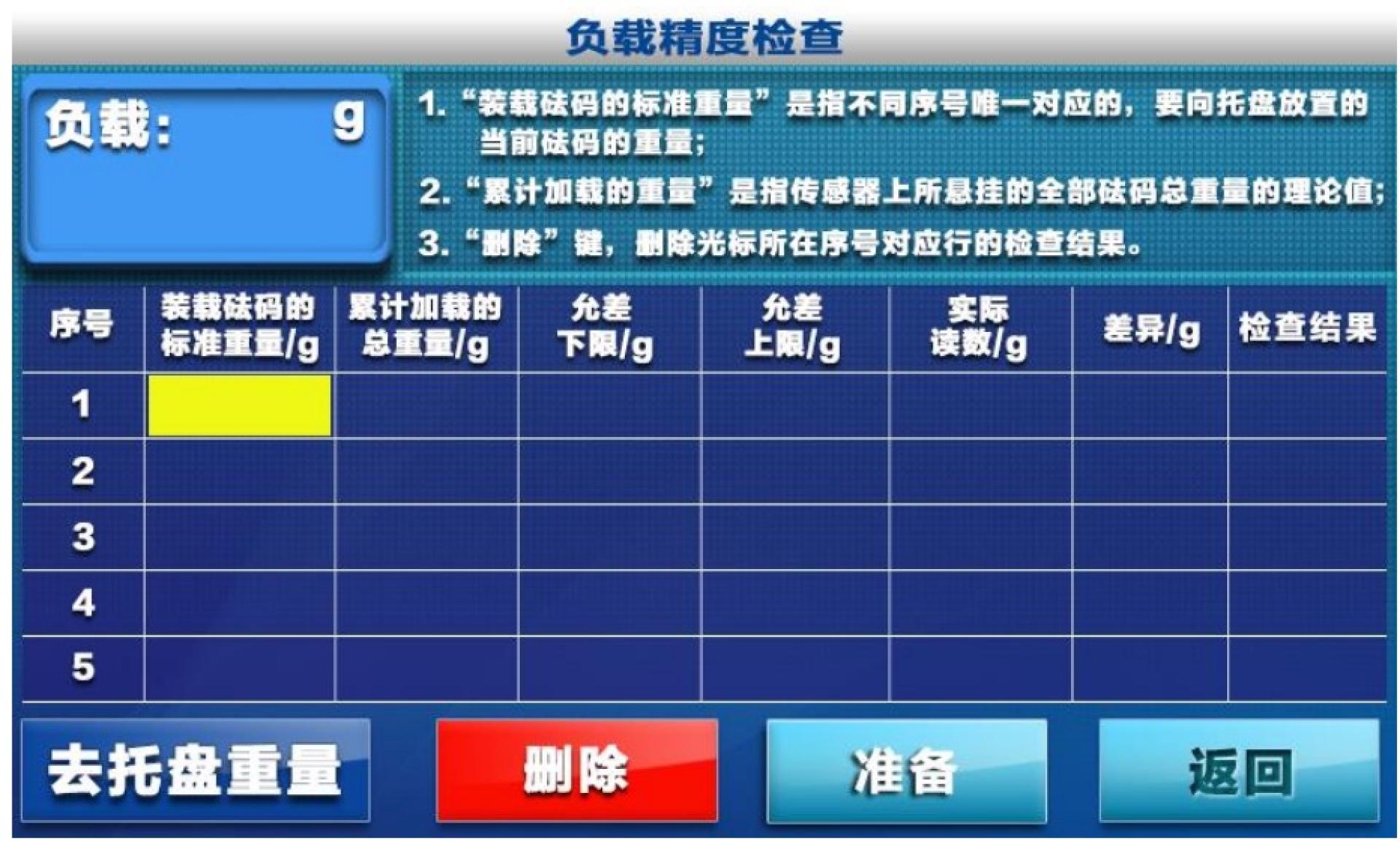

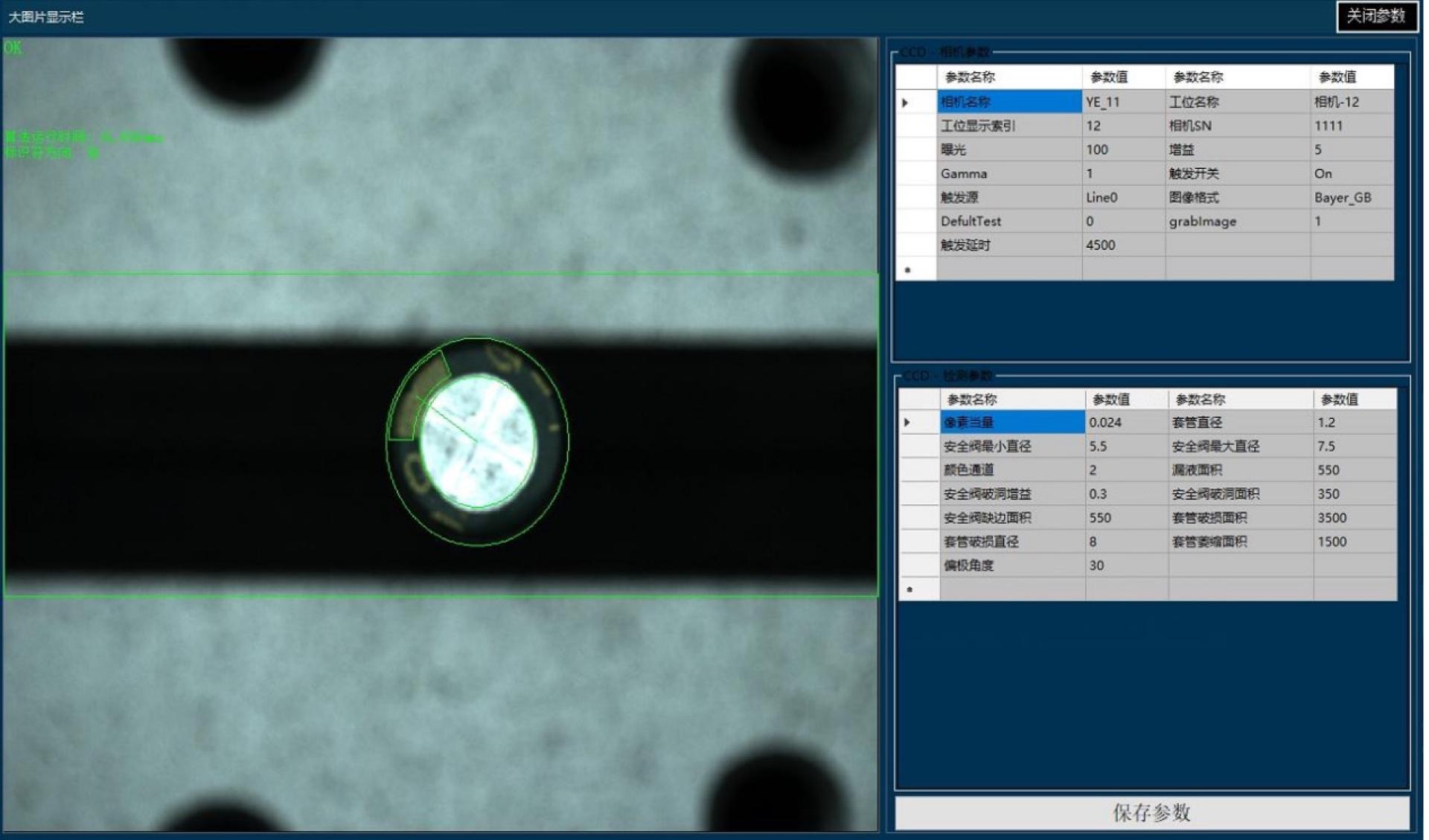

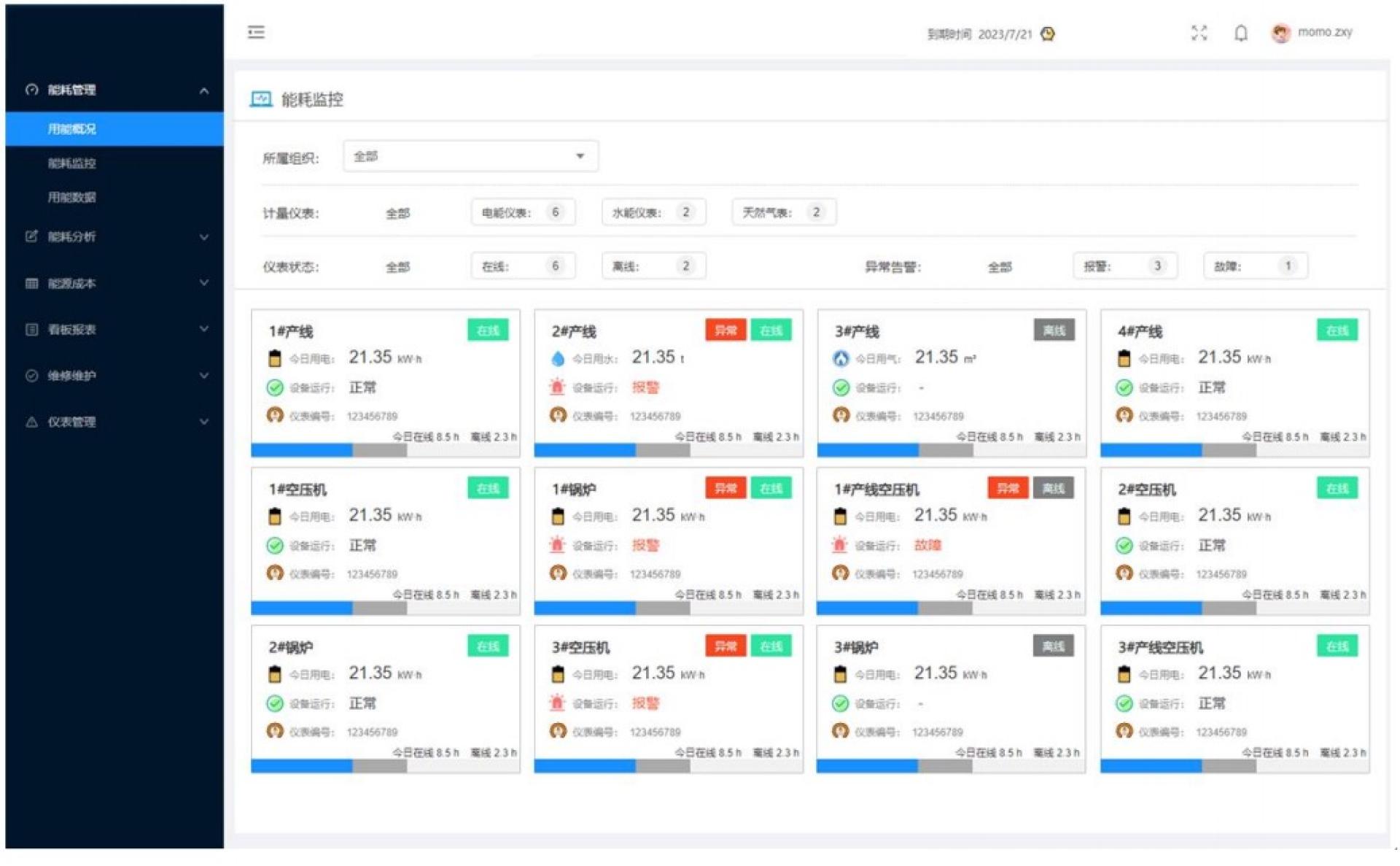

Equipped with high-precision monitoring and data analysis capabilities, the system integrates sensor networks and visual inspection units to collect real-time process parameters inside treatment kettles, including temperature, pressure, humidity, preservative concentration, wood moisture, and penetration rate—with accuracies of ±0.5% for concentration and ±1 °C for temperature. Following modular and formula-based design principles, it allows users to flexibly adapt to different wood species, service classes (C1–C5), and preservative types (ACQ, CuAz, CCA) through a configurable formula database, ensuring rapid production switching and versatility without altering the core algorithm.

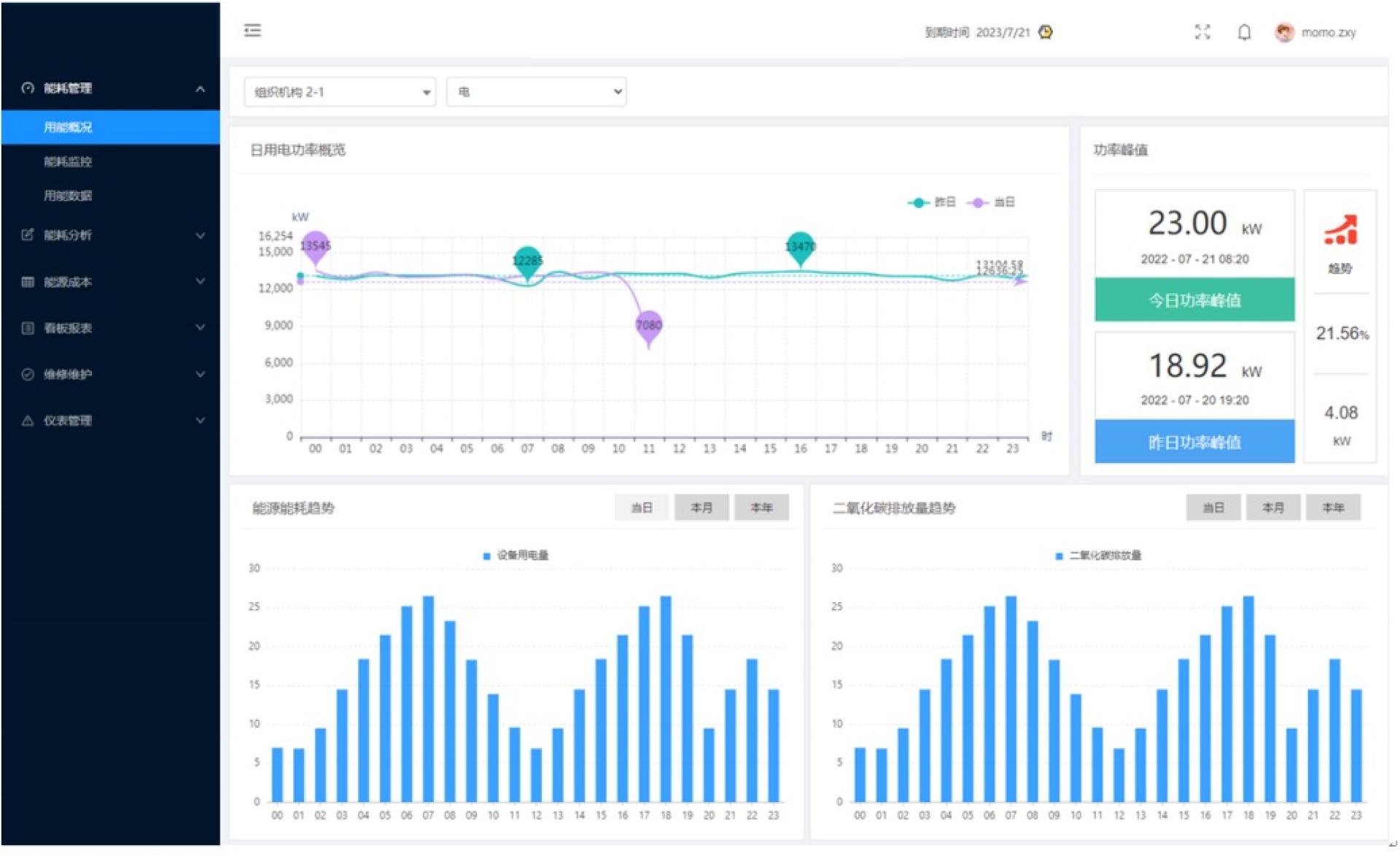

At its core lies a high-performance optimization engine powered by machine learning, capable of real-time analysis, trend prediction, and performance evaluation. When deviations occur—such as variations in wood density, preservative activity, or ambient temperature—the system activates a multi-objective optimization strategy that dynamically adjusts parameters such as vacuum level, pressure, holding time, temperature curve, and preservative feed rate. This enables precise closed-loop control of penetration depth and retention, improving treatment uniformity and efficiency while minimizing preservative consumption and energy use, thus enhancing both economic and environmental performance.

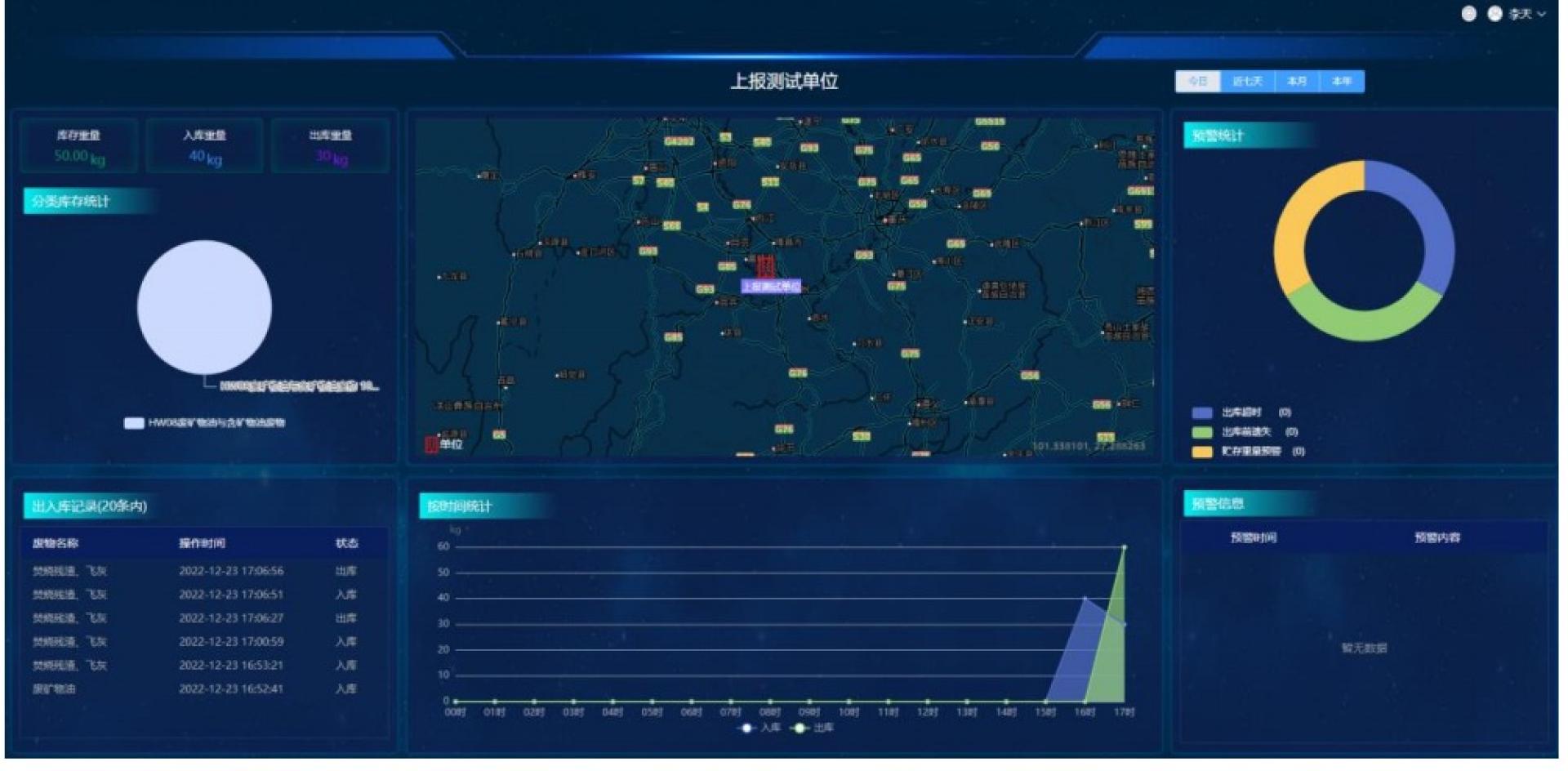

Deployed on factory servers or edge gateways, the system forms a continuous intelligent loop of “monitoring–evaluation–optimization–regulation.” Real-time data collected from distributed sensors is analyzed using material models and historical data to diagnose and predict treatment outcomes. The optimization engine then generates the ideal parameter set, and the control module automatically refines the process in real time—creating a self-adaptive, intelligent decision-support system that ensures consistent, optimal treatment quality across changing materials and conditions.

Credits

Entrant Company

Self

Category

Conceptual Design - Communication

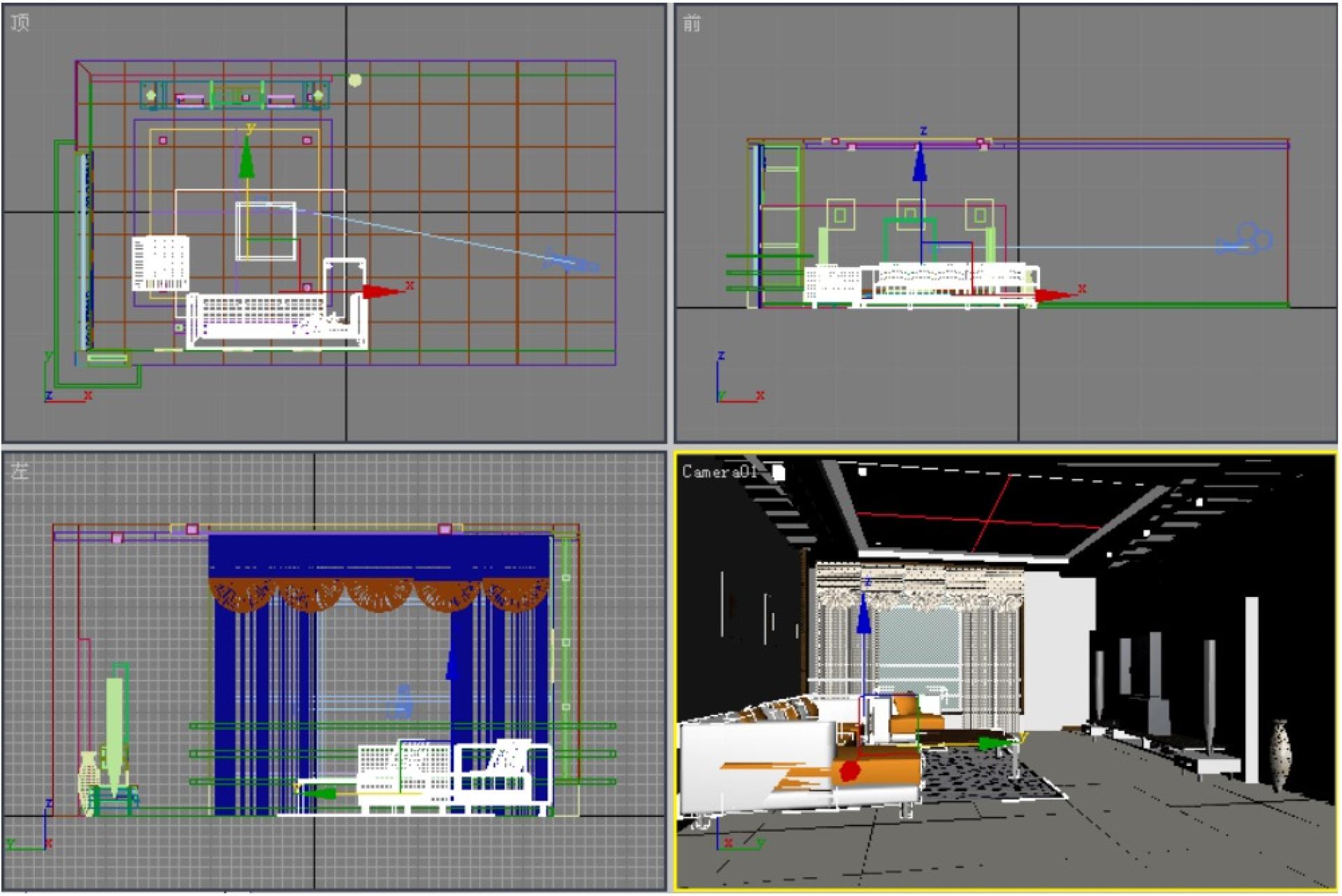

Entrant Company

YIFANGTIAN INTERIOR DESIGN

Category

Interior Design - Living Spaces

Entrant Company

W.Design 水設計室物所

Category

Interior Design - Residential

Entrant Company

ANTO Landscape Design Co.,Ltd

Category

Landscape Design - New Category