2024 | Professional

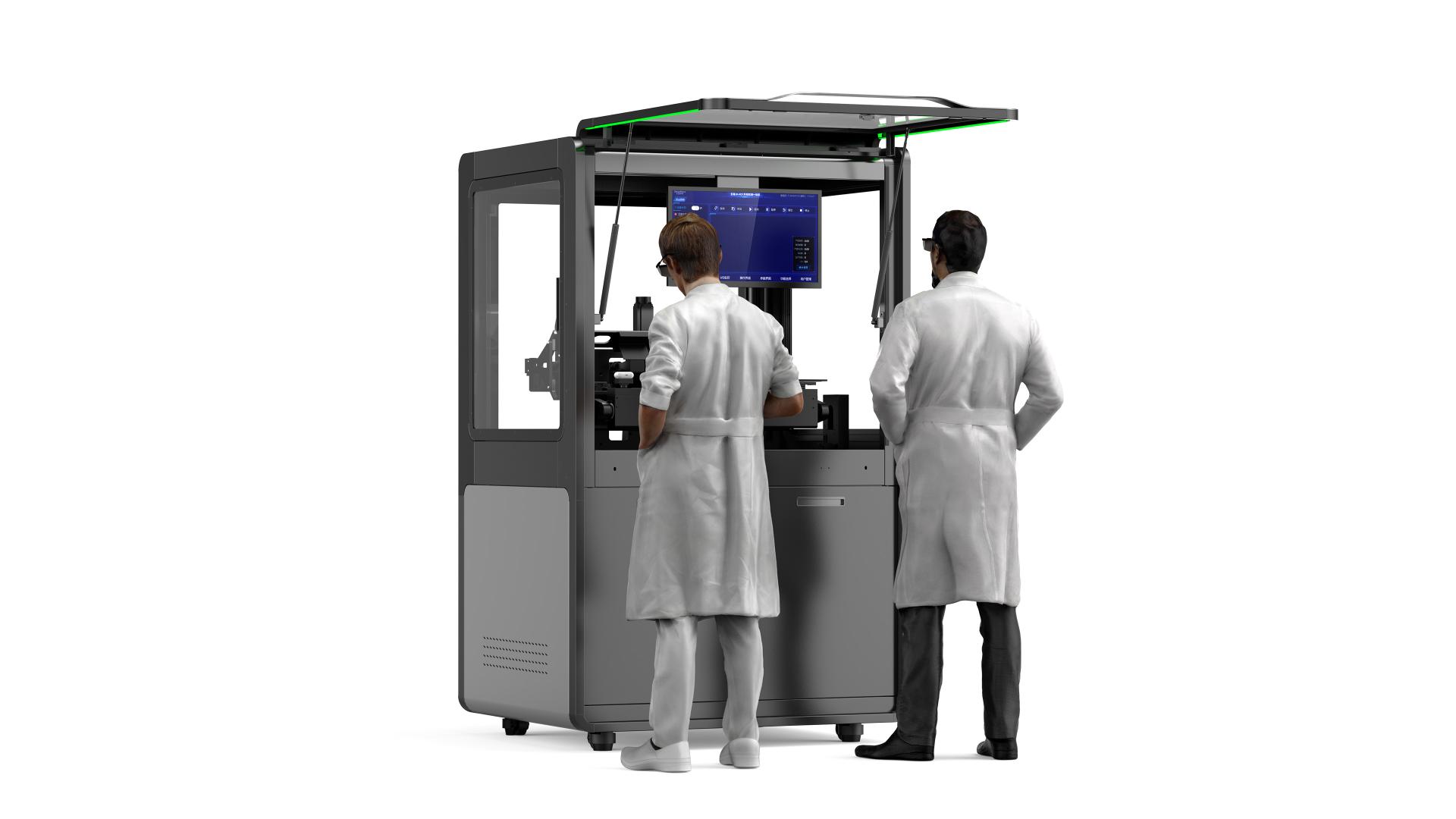

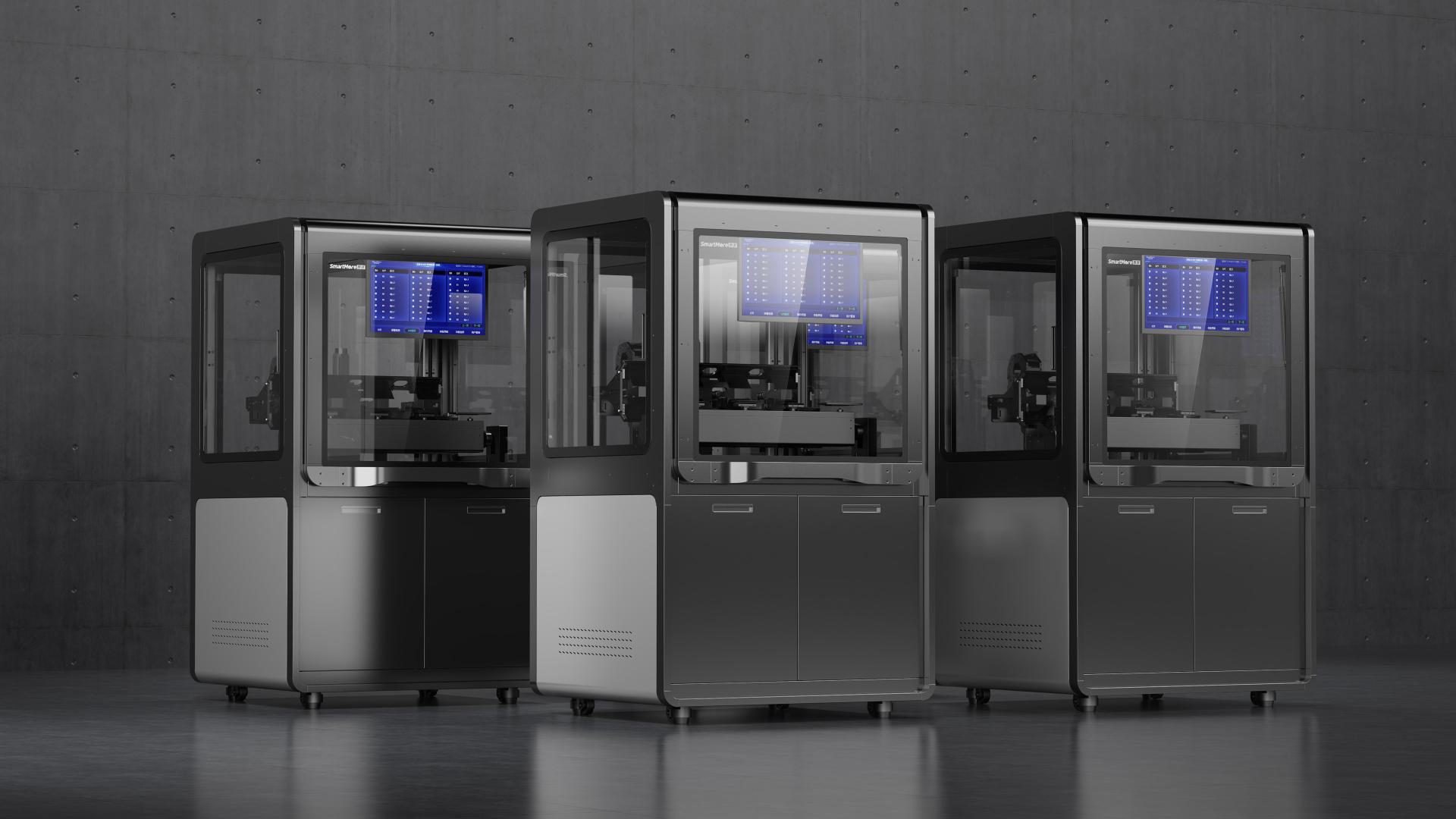

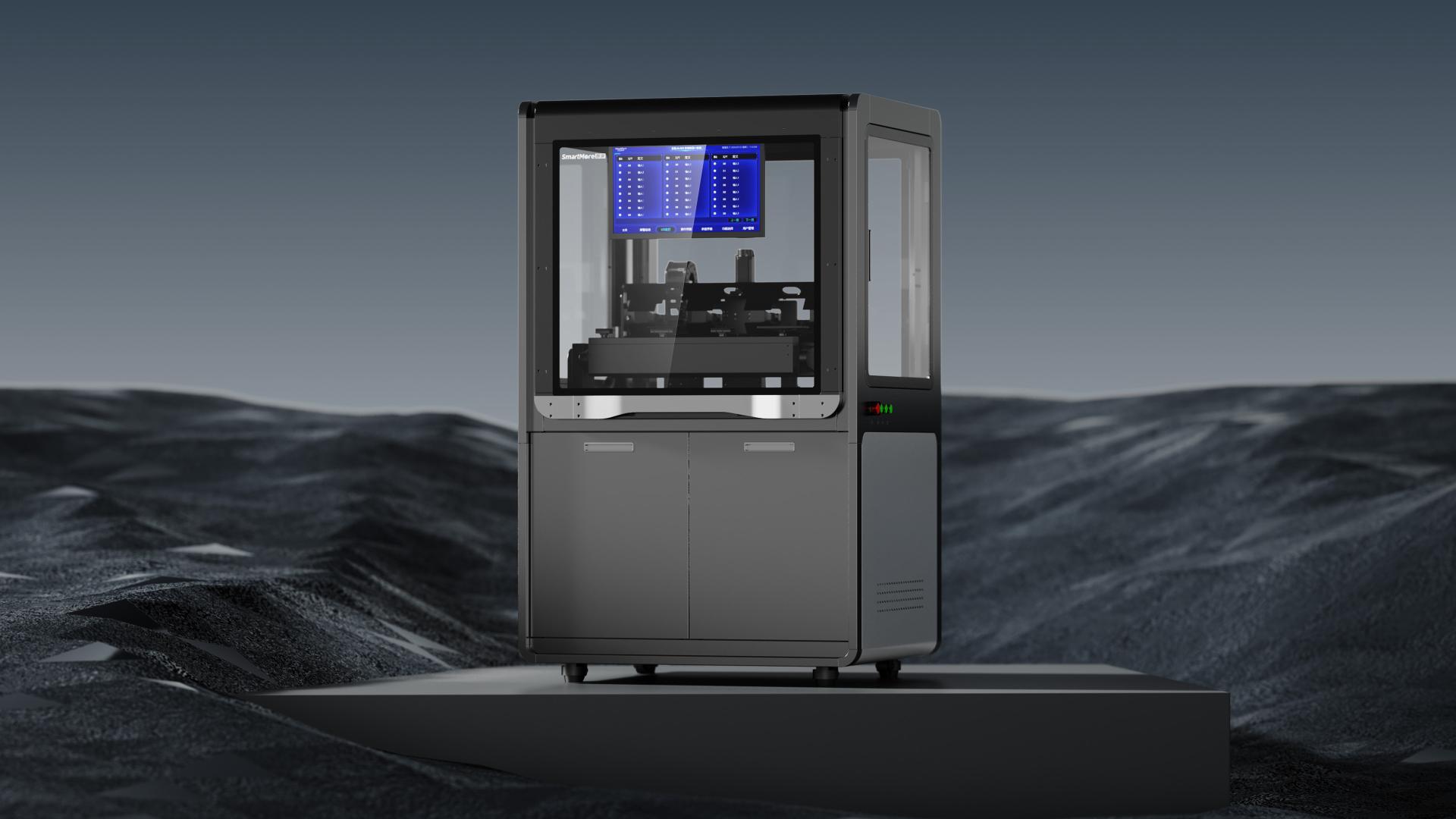

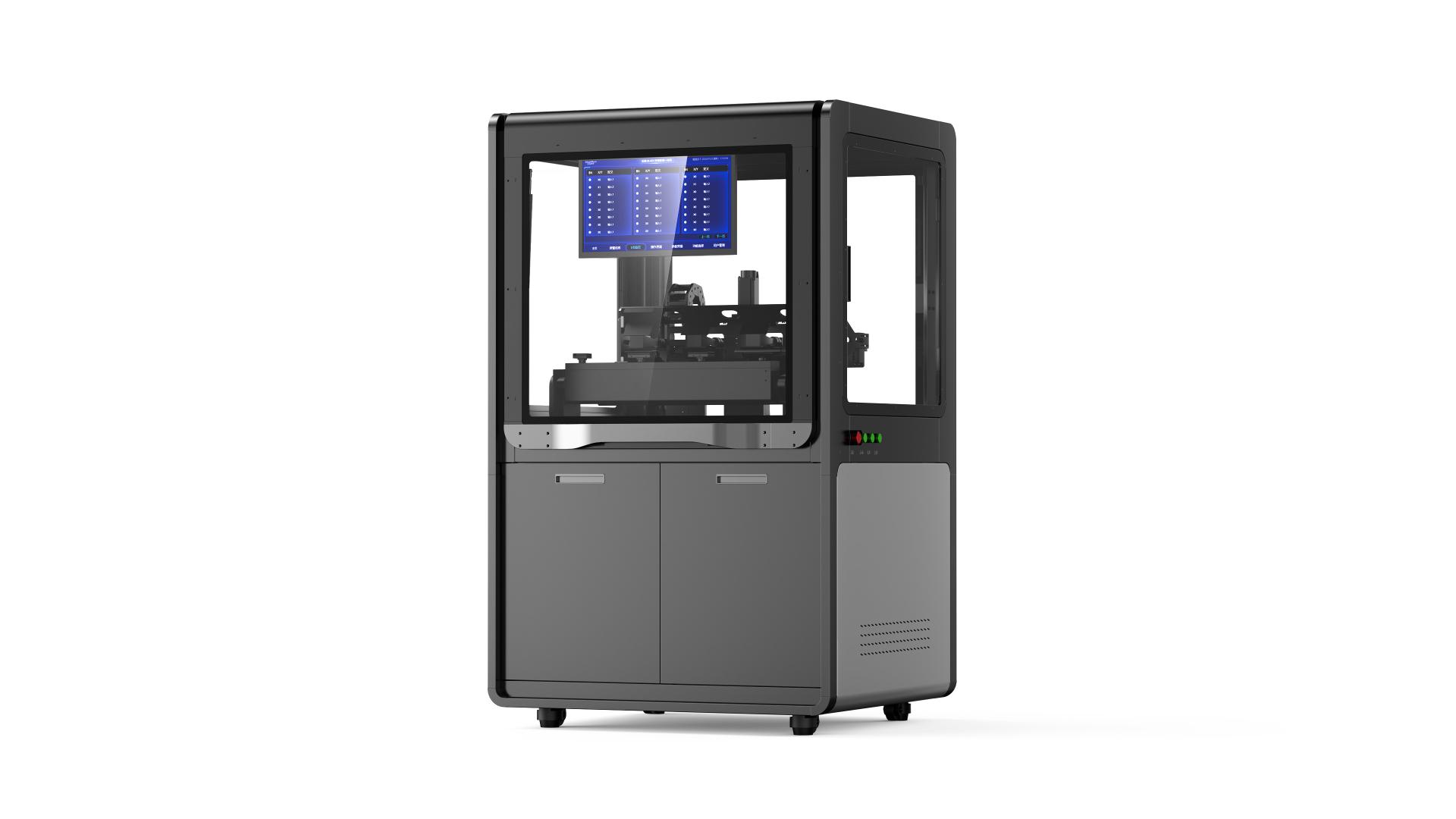

5-Axis AI-AOI Cosmetic Inspection Machine

Entrant Company

Shenzhen SmartMore Information Technology Co., Ltd

Category

Product Design - Industrial

Client's Name

Liu Shu, Huang Zhicheng, Yao Hengzhi, He Shuiyuan, Chen Feixu, Xing Zhiguang

Country / Region

China

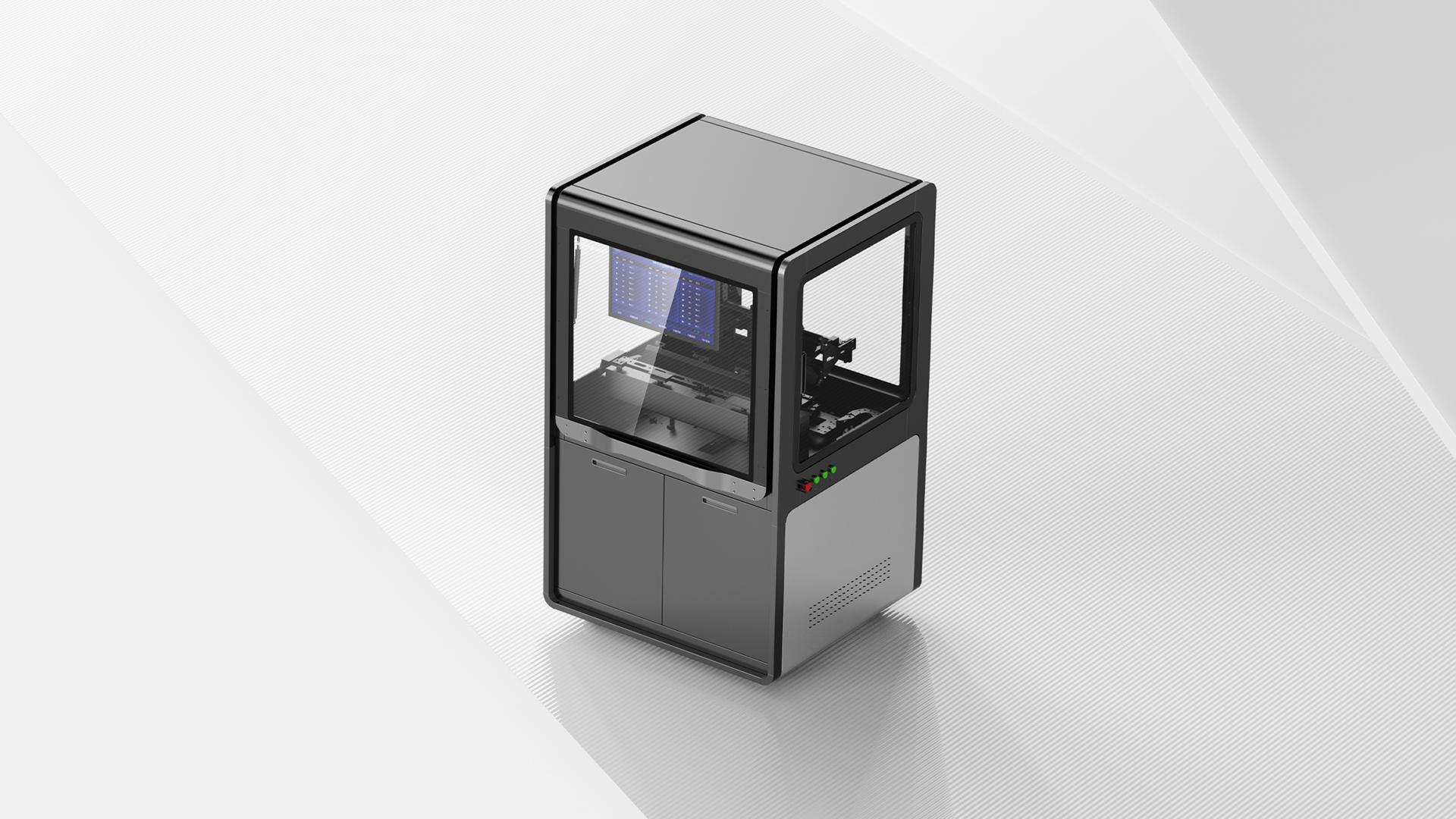

The 5-Axis AI-AOI Cosmetic Inspection Machine deeply integrates smart manufacturing technology and AI algorithms with multi-axis flexible coordination, enabling 360° effortless inspection on multi-curved surfaces, multi-position and irregular shapes of 3C products. Its wide coverage and customizable single and double-sided modules can be selected according to capacity and inspection needs, compatible with 3C products of varying materials and sizes. The machine emphasizes intelligent interaction and user-friendly operation, offering comprehensive functionality and ease of use, setting a new benchmark for future industrial inspection equipment.

This machine introduces an innovative five-axis coordination design, which effectively meets the inspection needs of complex structures such as curved surfaces and irregular shapes. The high-precision five-axis coordination system enables 360° inspection without any blind spots, allowing for synchronous control and dynamic adjustment. This system ensures that every detail is accurately detected, significantly enhancing inspection precision and efficiency while maintaining the machine's exceptional adaptability to diverse inspection tasks, perfectly meeting modern industry's stringent demands for both high precision and efficiency.

The machine features an interchangeable lighting for fixed and fly triggering, supporting 2D, 2.5D, and 3D imaging modes, allowing comprehensive coverage of defects, achieveing a high detection rate. It also offers flexible adaptation to different inspection requirements, allowing free selection and configuration based on material and detect type, with multiple light source options such as coaxial, bar, ring, backlight, and combination lighting available. With its versatility and adjustability, the machine can accurately capture even the finest cosmetic defects in complex environments, providing high-quality inspection results and strong technical support.

The inspection process adopts handshake docking to transfer material inside for front and back inspection, avoiding redundant motions such as pick-and-place and flipping. It can also reduce the number of handovers and minimize the risk of product injuries. The multi-station simultaneous inspection ensures the smachine can detect up to 40 products concurrently. Flying Trigger Technology can capture motion + image under 0.12s, with a UPH of up to 5,000, effectively replacing 20 workers and significantly boosting work efficiency. Additionally, it supports real-time monitoring and remote control, enabling users to adjust inspection parameters and view results at any time.

Credits

Entrant Company

China Mobile (Chengdu) Information and Communication Technology Co., Ltd.

Category

Product Design - Educational Tools / Teaching Aids / Learning Devices

Entrant Company

K More Interior Design

Category

Interior Design - Living Spaces

Entrant Company

Juwon Jeon

Category

Fashion Design - Other Fashion Design

![MUSE Design Awards Winner - [objt]](upload/entry/thumb/1703588864_thumb_217467.png)

Entrant Company

Zhipeng Pan

Category

Conceptual Design - Products