2025 | Professional

Automatic laser wire feeding welding machine

Entrant Company

Tianpeng Wang

Category

Product Design - Industrial

Client's Name

Tianpeng Wang

Country / Region

China

To overcome the limitations of conventional stainless steel sanitaryware welding—such as surface deformation, insufficient joint strength, and aesthetic flaws—this innovative automatic laser wire feeding welding machine was engineered to deliver deep-penetration welding, structurally reliable bonds, and polish-ready surface quality.

At its core, the adaptive wire feeding welding machine dynamically calibrates wire deposition rates with welding velocity, ensuring consistent filler material integration for uniform melt pool formation. This results in full-depth weld penetration, enhanced mechanical durability, and seamless post-processing finishes, eliminating manual grinding.

The system’s multi-axis vision-guided alignment module further elevates precision. By combining high-resolution optical tracking with synchronized motion control, it autonomously maps optimal trajectories for both the laser beam focal point and wire nozzle, enabling submillimeter welding accuracy. Operators supervise the process remotely via an integrated display, minimizing exposure to arc radiation. Notably, the electrically isolated mold configuration (utilizing compliant, non-conductive materials) prevents spark-induced surface damage, ensuring pristine workpiece integrity throughout production.

Credits

Entrant Company

YA-MAN LTD.

Category

Product Design - Personal Care

Entrant Company

Timemory design

Category

Interior Design - Residential

Entrant Company

ZHI YAO CONSTRUCT CO., LTD.

Category

Conceptual Design - Public Space

Entrant Company

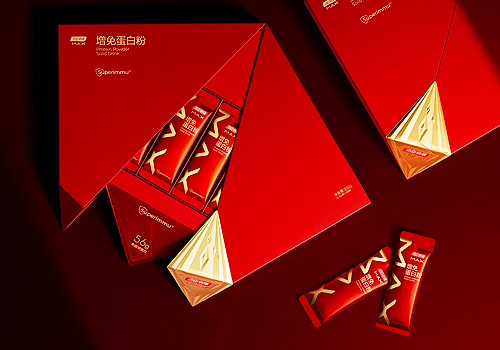

BYHEALTH Co., Ltd.

Category

Packaging Design - Health & Wellness