2025 | Professional

Castomize - TessaCast

Entrant Company

A*Star Innovation Factory @ SIMTech

Category

Product Design - Medical Devices

Client's Name

Castomize Technologies Pte. Ltd.

Country / Region

Singapore

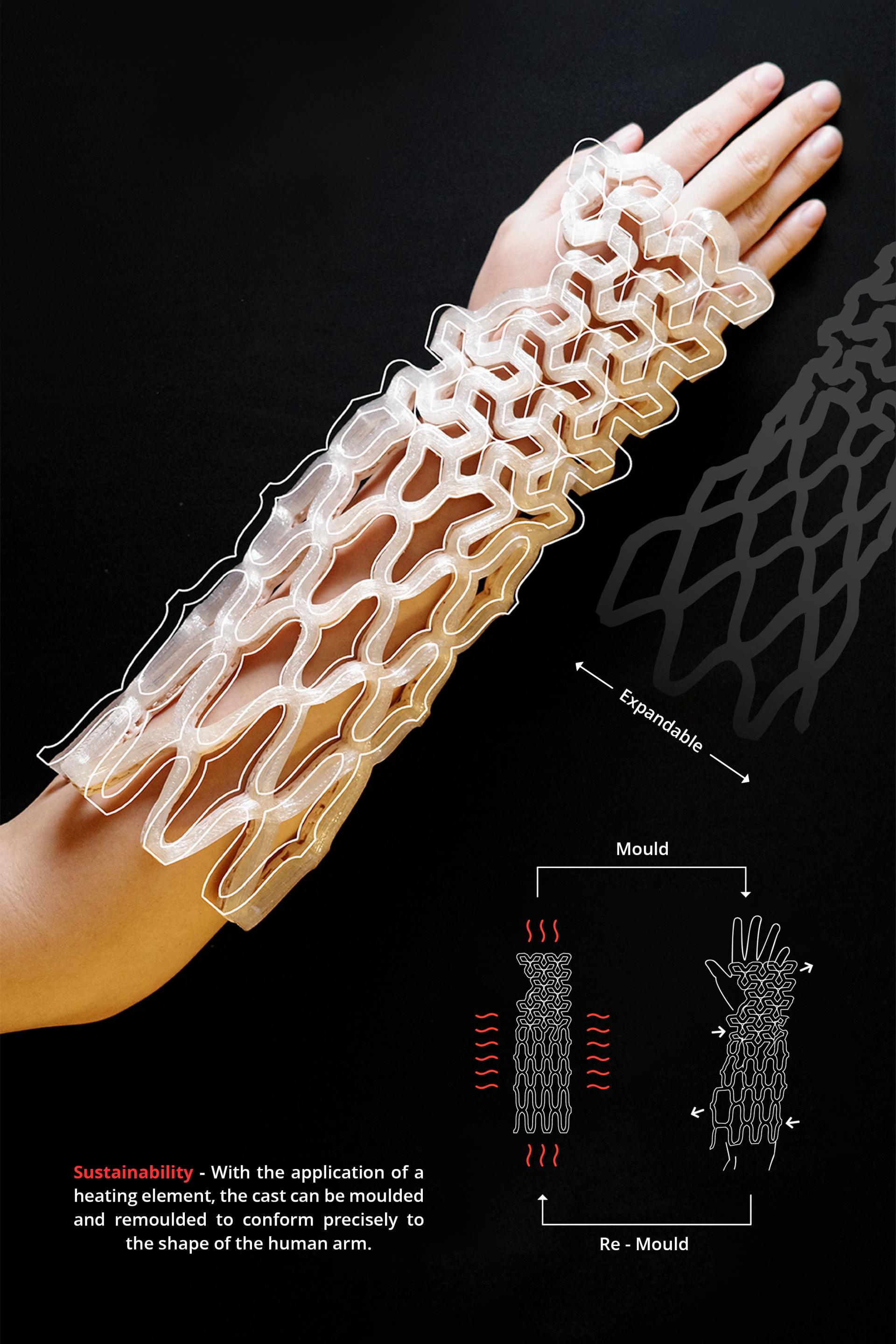

Revolutionising Limb Immobilisation with 4D-Printed Casting

Each year, millions of people endure the discomfort and inconvenience of traditional fiberglass casts, a rigid protective shell that is neither patient-friendly nor sustainable. Castomize is revolutionizing orthopedic care with a groundbreaking 4D-printed cast that redefines fracture recovery named Tessacast. Designed to be skin-compatible, waterproof, reusable, and self-moulding, Tessacast offers superior comfort, functionality while dramatically reducing environmental impact, setting the future standard for immobilisation.

A Patient-Centric Approach

Traditional plaster and fiberglass casts are cumbersome, rigid, and restrictive, leading to discomfort, skin irritation, and hygiene challenges. Tessacast combines an advanced blend of materials with curated tessellated design with ergonomic design, to deliver unmatched comfort and flexibility to a wide range of patients with different sizes. Patients can shower freely, maintain hygiene effortlessly, and continue daily activities with minimal disruption. The breathable structure minimizes skin discomfort and enhances the overall well-being of each patient.

Efficiency & Accuracy for Healthcare Providers

Healthcare professionals work with great attention to provide the highest quality care. TessaCast assists them with an expandable, pre-molded cast featuring a one-size-fits-most tessellated design, ensuring a precise fit with minimal manual adjustment. This reduces application errors, saves time, and streamlines workflows by minimizing resource and manpower requirements. With at least a 50% increase in efficiency, it lowers costs, eases staff workload, and enables healthcare professionals to dedicate more time to patient care.

Sustainability & Reusability

TessaCast revolutionizes sustainable orthopedic care by reducing waste by at least 30%. Unlike traditional single-use casts, its remoldable and reusable design eliminates the need for multiple replacements during the 6–8 week healing period, addressing inefficiencies caused by muscle atrophy. This eco-friendly solution lowers waste and costs, enhancing patient care while protecting the environment.

Industry-Disrupting Innovation

Tessacast is disrupting the orthopedic industry with the world’s first 4D-printed limb immobilization solution. Challenging traditional fiberglass casts with a groundbreaking alternative that is self-molding, reusable, and patient-optimized. By leveraging cutting-edge technology, Castomize is not just competing with industry incumbents, it is redefining the future of orthopedic care on a global scale.

Credits

Entrant Company

L&H Space Design

Category

Interior Design - Flagship Store

Entrant Company

HAOStudio / EASY Studio

Category

Interior Design - Restaurants & Bars

Entrant Company

Comfort Workspace

Category

Furniture Design - Office

Entrant Company

AX Film

Category

Transportation Design - Auto Accessories & Interiors