2025 | Professional

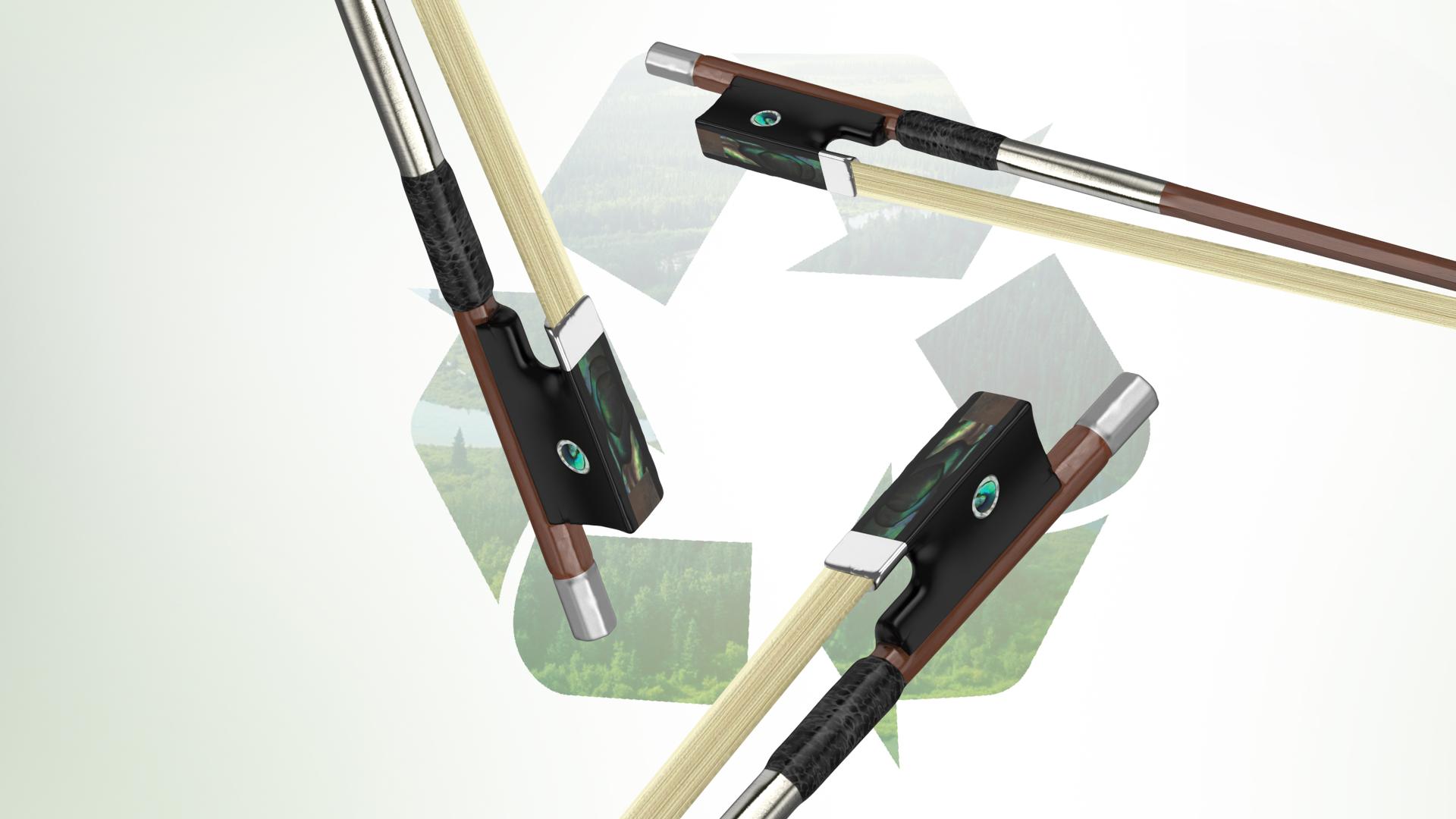

OBambow

Entrant Company

Banbao Workshop

Category

Product Design - Music, Audio & Sound

Client's Name

Country / Region

OBambow breaks with centuries of tradition in bow-making by pioneering a new solution using renewable bamboo and synthetic ebony. This innovative approach delivers performance comparable to, and even surpassing, that of Pernambuco wood bows. Against the backdrop of the impending global ban on Pernambuco wood trade, OBambow emerges as the industry's first high-end alternative bow that is mass-producible, replicable, and delivers consistent performance. Not only does it fill the material void for professional-grade bows, but it also offers players a feel and tonal quality approaching that of the finest antique bows. Its unique bamboo composite and structural reinforcement process achieve top-tier levels of stiffness, elasticity, and sound transmission, truly realizing a dual revolution in both material and craftsmanship. The creation of OBambow stemmed from interdisciplinary thinking—a desire to merge instrument making with environmental conservation and explore sustainable alternatives to endangered woods. The project was inspired by the founder's participation in the 2023 International Pernambuco Conservation Initiative conference, which sparked the decision not just to find a substitute, but to surpass the original material in both performance and craftsmanship. This vision drove the first successful application of bamboo in the professional bow-making field while establishing a standardized, scalable production system, charting a new course for the future of the industry. Bamboo has a growth cycle of just 3-5 years, offering high yields and sustainable harvesting that drastically reduces reliance on tropical rainforest resources. Compared to traditional wooden bows, bamboo offers superior maintenance advantages. Wooden bows are prone to breaking from impacts or drops, resulting in high maintenance costs. In contrast, bamboo bows exhibit excellent toughness and high impact resistance. They are extremely difficult to break during regular use, which significantly enhances their durability and reliability while lowering both the risks and costs of maintenance. In its material selection and processing, OBambow minimizes the use of chemical coatings, lessening the environmental impact of its production. Globally, OBambow presents a solution that balances performance, cost, and environmental responsibility, offering a truly viable path forward in response to the Pernambuco wood ban.

Credits

Entrant Company

Anhui Kudouding Technology Development Co., Ltd.

Category

Product Design - Baby, Kids & Children Products

Entrant Company

Isaac

Category

Fashion Design - Streetwear (NEW)

Entrant Company

Qiu Yikai

Category

Interior Design - Residential

Entrant Company

Xi'an Yiwen Brand Design Co., Ltd

Category

Packaging Design - Dairy, Spices, Oils, Sauces & Condiments