2025 | Professional

Newly One-Piece and Green Material

Entrant Company

YA-MAN LTD.

Category

Product Design - Textiles / Floor Coverings

Client's Name

Country / Region

Japan

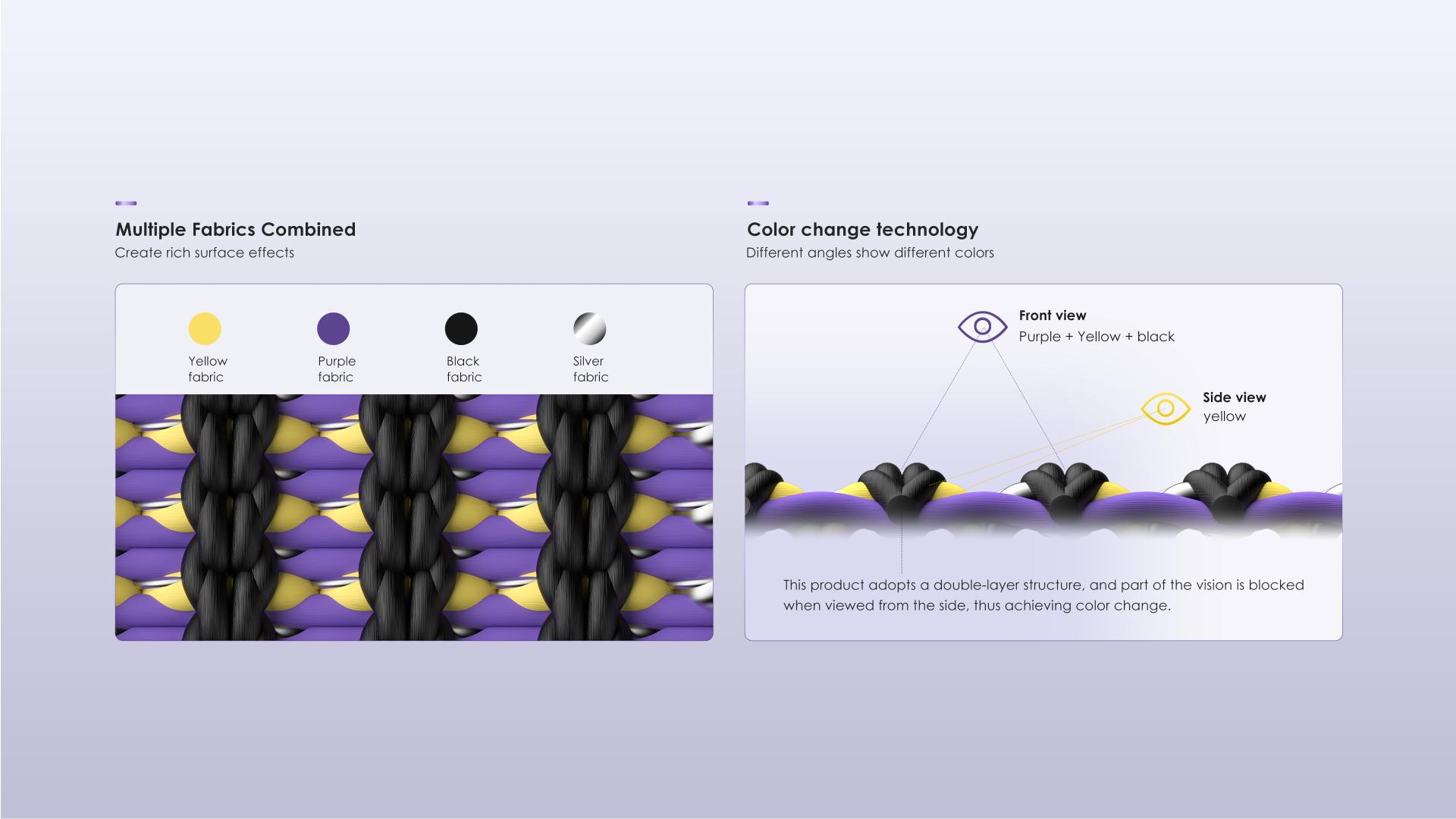

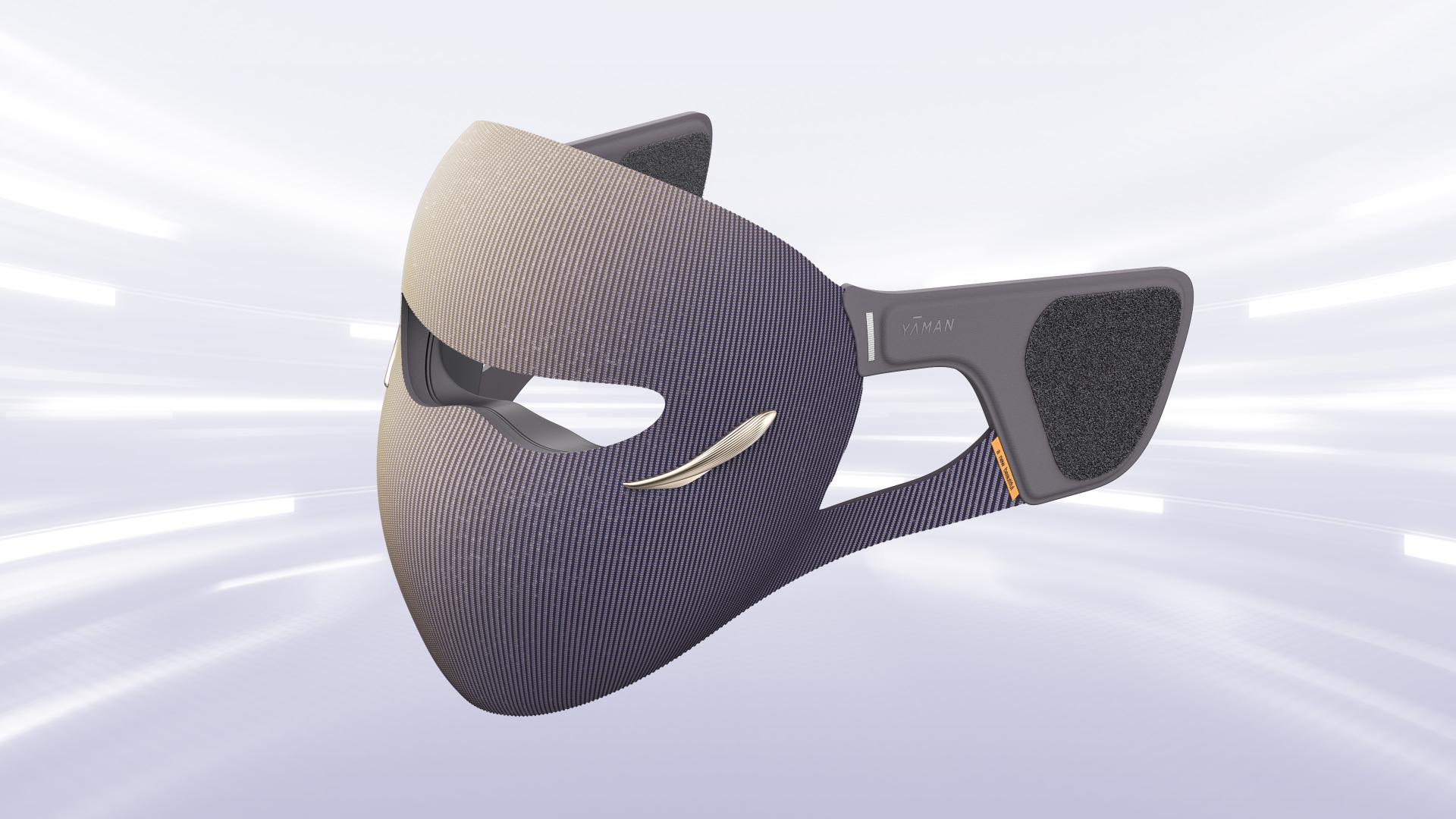

Flying weaving technology, an innovative technique originally from the athletic footwear industry, has now been ingeniously applied to the newly one-piece and green material, initiating an unprecedented cross-industry revolution. Through computer programming and intelligent manufacturing with flat-knit machines, we have achieved a tight knitting of the upper and lower fabric layers, not only obtaining the desired size and pattern but also giving the mask material an unprecedented 3D texture and lightness. This represents a disruptive challenge to traditional fabric manufacturing by flying weaving technology and a bold exploration of future design trends.

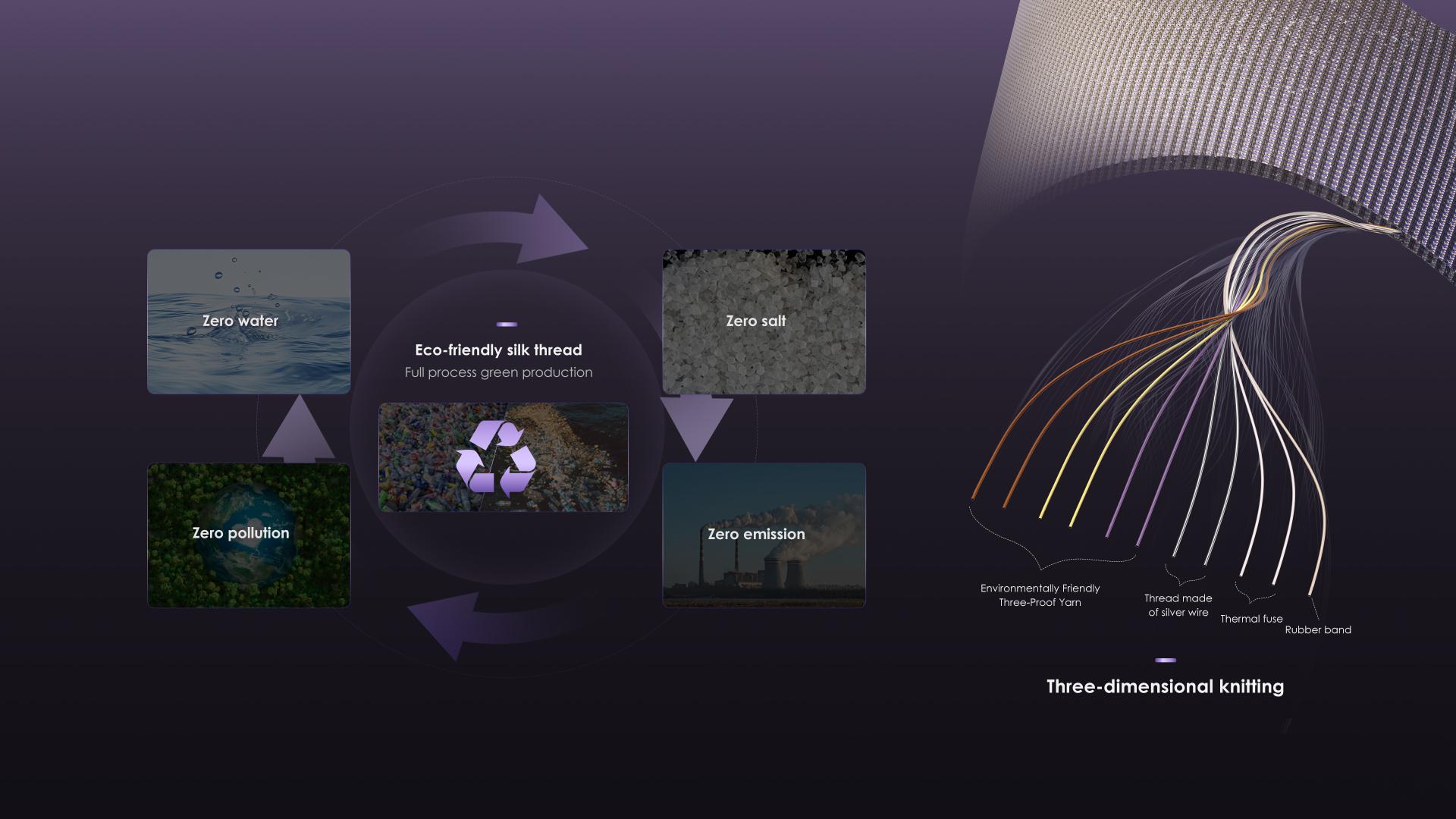

While pursuing technological innovation, we are fully aware of the importance of environmental protection. Therefore, several eco-friendly measures have been adopted in the production process of the newly one-piece and green material. The application of special shuttles and weaving devices reduces yarn consumption and energy usage, enhancing weaving efficiency. The introduction of an automatic control system has enabled fully automated operations, simplifying the weaving process and reducing manpower. Notably, we have adopted eco-friendly, renewable, and three-proof yarn, along with waterless dyeing technology, converting recycled plastic bottles and marine waste into non-polluting and biodegradable materials. The dyeing process uses zero water, zero salt, and produces zero emissions, truly achieving green production and reducing the burden on the Earth.

We have innovatively applied this newly one-piece and green material to our light energy mask. Compared to traditional mask materials, this new fabric offers exceptional softness, allowing for a close fit against the skin and ensuring that light maintains the same distance across different areas of the face. This clever combination significantly enhances the uniformity of light exposure, which can balance the intensity of light energy. Further, the light energy mask achieves a remarkable functional optimization, providing users with an unprecedented experience.

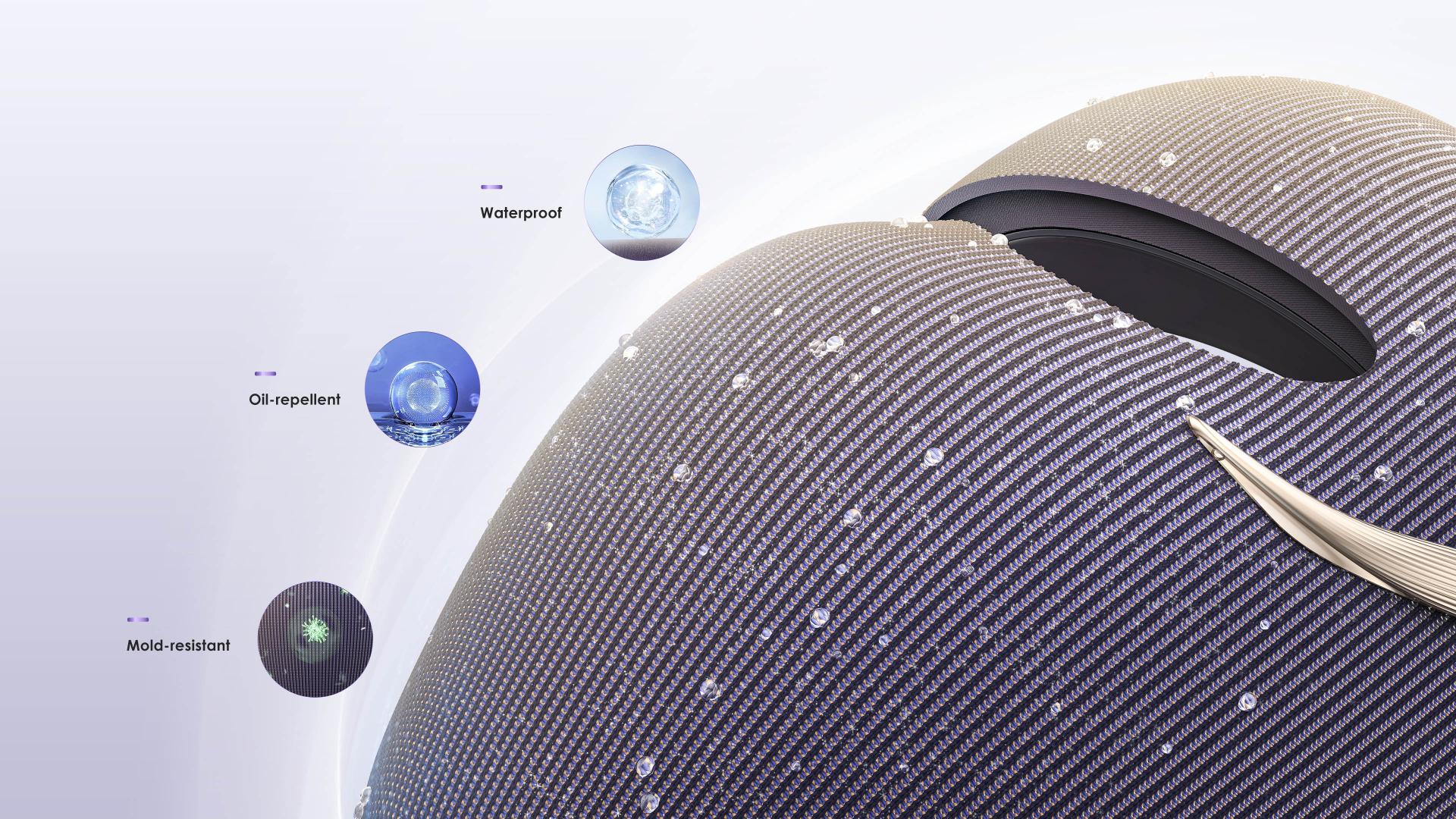

Another highlight of the newly one-piece and green material lies in its three-proof performance: waterproof, oil-repellent, and mold-resistant. This feature is attributed to the eco-friendly and renewable three-proof yarn we use. In humid areas or environments, the mask material will not mold, discolor, or develop bacteria, effectively resisting the intrusion of cosmetics and oil stains.

Credits

Entrant Company

Shenzhen Airt Creative Co., Ltd.

Category

Interior Design - Showroom / Exhibit

Entrant Company

Shanghai Xinteng Clothing Co., Ltd.-Zhu Hui

Category

Conceptual Design - Technology

Entrant Company

JENME Design

Category

Interior Design - Commercial

Entrant Company

UNIVERISTY OF THE ARTS LONDON

Category

Conceptual Design - Healthcare