2025 | Professional

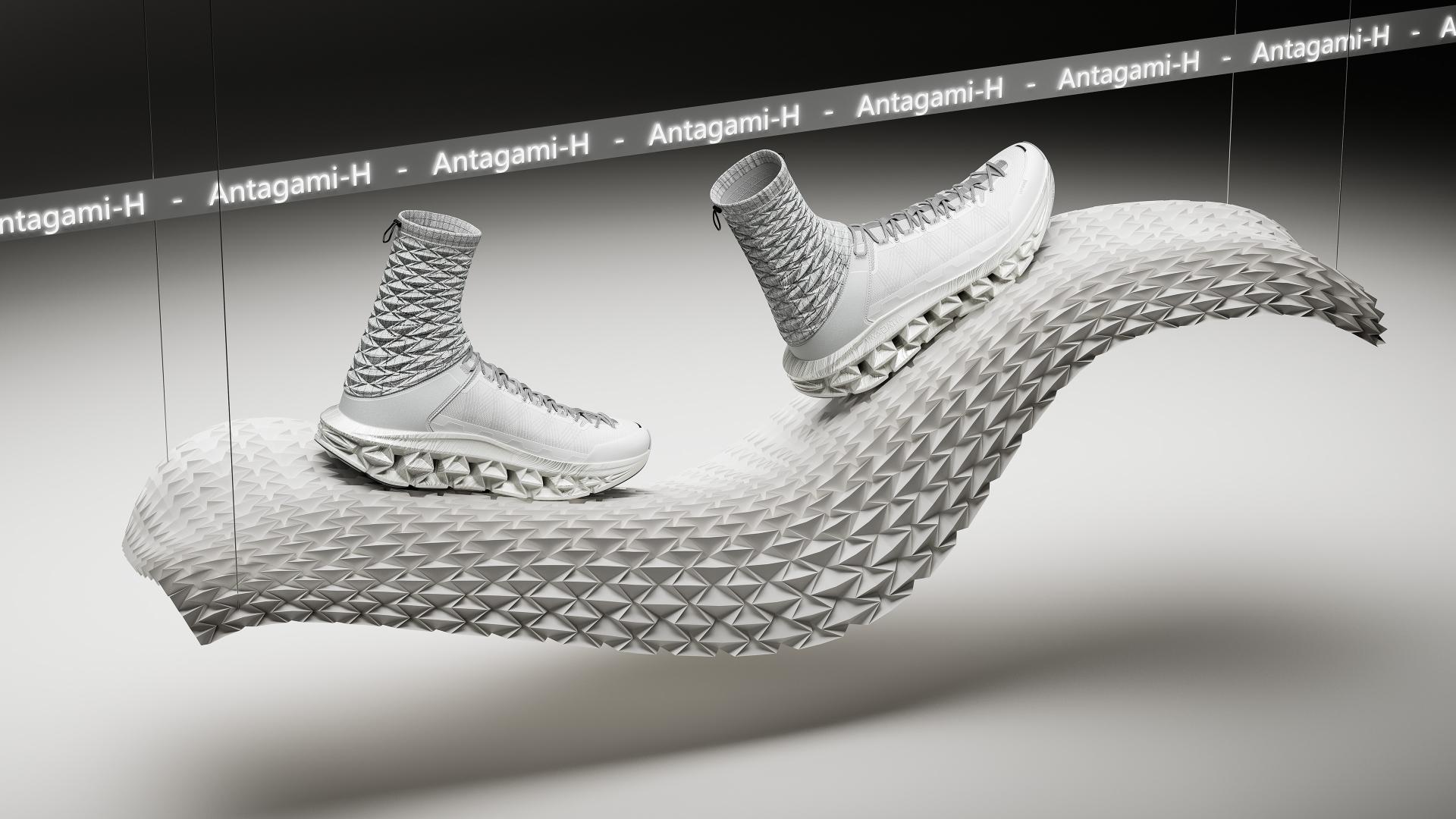

Antagami-H

Entrant Company

ANTA (China)Co.,Ltd.

Category

Product Design - Outdoor & Exercise Equipment

Client's Name

Fei Zheng, Robert Fuller, Yilong Liu, Zhihao Xie, Guanghui Long, Fuquan Ye, Zhenjia Wu, Zujiang Xiong

Country / Region

China

When a millennium of Eastern origami art meets modern engineering science, a creative spark ignites. We firmly believe that genuine innovation is not conjured from thin air, but deeply rooted in profound culture. Antagami-H takes this as its core by boldly fusing the intricate structures of origami with the performance demands of athletic footwear. In a landscape of homogenized competition, it carves out a new path that blends cultural heritage with technological aesthetics. The beauty of Antagami-H origami structure is naturally enshrined in the midsole design. By parametrically adjusting the origami unit, we can achieve customized cushioning and rebound performance in different areas of the sole, meeting complex athletic demands. Its dynamic adaptive properties allow the sole to maintain stability and balance through localized compression and deformation on uneven terrain, significantly enhancing athletic performance. Simultaneously, the hollowed-out structures resulting from origami effectively reduce the shoe's weight, achieving an ultra-lightweight design. Antagami-H utilizes the innovative Mucell® microcellular physical foaming extrusion process. This cutting-edge process not only endows the midsole with excellent moldability—making the sole‘s folding function more effective and the structural edges more defined—but also naturally forms natural, delicate flow patterns on its surface. These flow patterns resemble the unique fiber textures formed during the pressing of natural paper pulp, perfectly aligning with the paper-like texture inherent in the origami concept. Both the upper and sole uniformly adopt TPU material, achieving a "one shoe, one material" concept. This not only significantly enhances the entire shoe's recyclability but also simplifies end-of-life processing. Specifically, the upper primarily uses bio-based TPU (with some raw materials derived from renewable plant resources like corn and castor beans). While maintaining the excellent properties of traditional TPU (such as high elasticity and abrasion resistance), it significantly reduces carbon emissions during production. Furthermore, the upper fabric innovatively incorporates eco-friendly seaweed yarn in certain areas. Its lightweight and breathable properties endow the upper with excellent wearing comfort. The appearance of the shoe is a masterful convergence of Eastern aesthetics and modern design.

Credits

Entrant Company

Chongqing Design Institute Co., Ltd.

Category

Interior Design - Hotels & Resorts

Entrant Company

Bosic Integrated Marketing Ltd.

Category

Conceptual Design - Exhibition & Events

Entrant Company

Shanghai Jianyuan Landscape Planning and Design Co., Ltd

Category

Landscape Design - Residential Landscape

Entrant Company

Guanyu Tao & Zhaoxiong Han

Category

Architectural Design - Tiny Houses / Compact Living (NEW)