2025 | Professional

IGE PPF -Happy

Entrant Company

Shanxi Xuanyuan IGE New Materials Co., Ltd.

Category

Product Design - New Category: Car Film

Client's Name

Country / Region

China

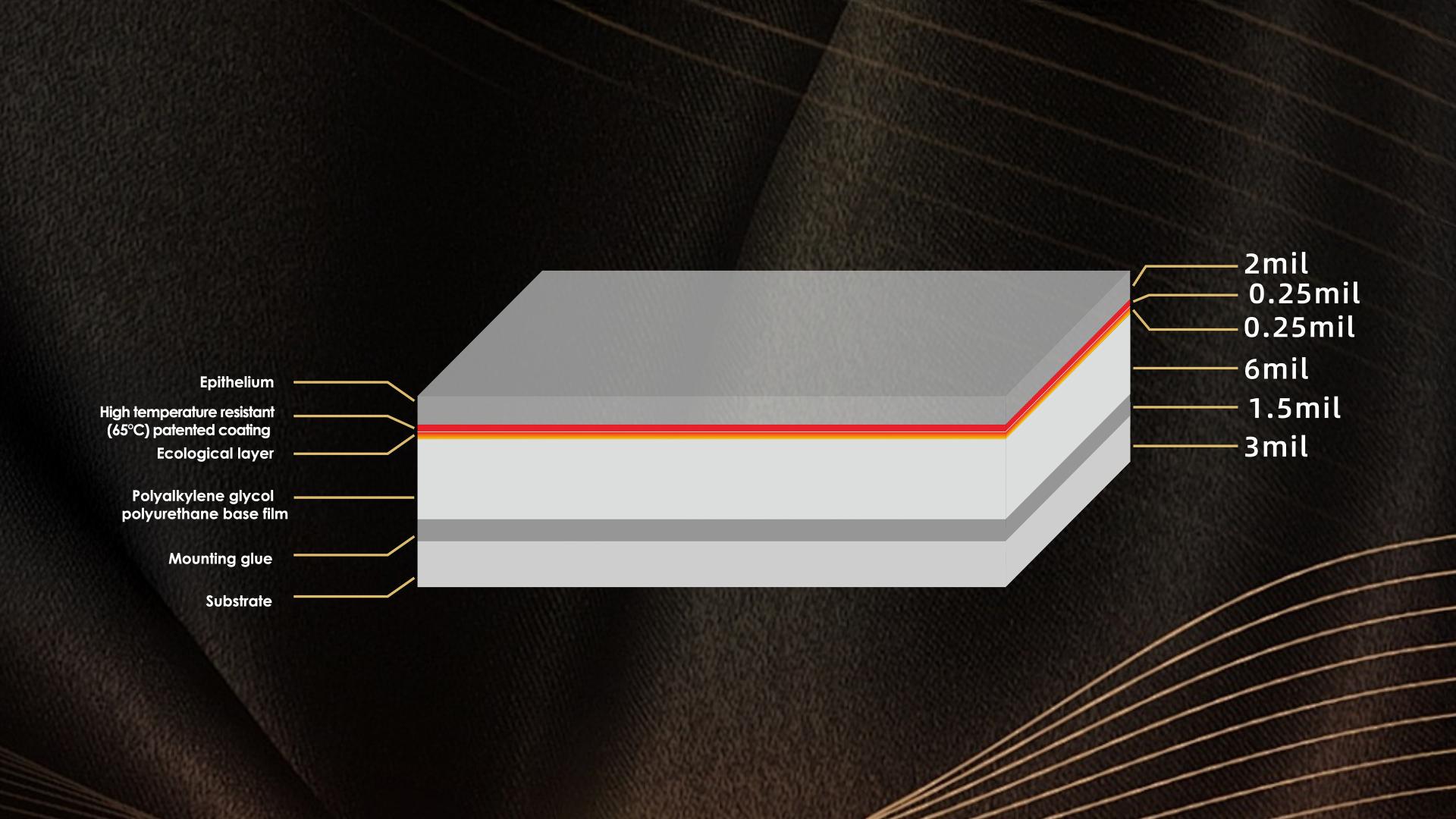

The IGE paint protection film effectively addresses the issue faced by traditional paint protection films under intense summer heat. High temperatures can enlarge the molecular gaps in the coating, allowing external contaminants—such as tree sap, insect remains, bird droppings, rainwater, and dust—to penetrate the base layer, leading to surface staining, reduced gloss, and significantly shortened lifespan. IGE’s innovative Athtemp® high-temperature corrosion-resistant technology solves these durability challenges, combining superior balancing brightness and scratch resistance to comprehensively enhance paint protection performance. The multi-layer interpenetrating network structure enables precise control over the structure and sequence distribution of polyurethane molecular chains during polymerization. This forms a dense nanogrid with nanoscale voids. Even when the car paint surface temperature exceeds 65°C, the coating retains its compactness, effectively blocking contaminants such as tree sap, insect remains, and bird droppings. This prevents pollution penetration and preserves the film's glossy finish. IGE paint protection film not only addresses the short lifespan and high maintenance costs of traditional films under high-temperature conditions but also significantly reduces replacement frequency with an extended protection period of 7–10 years, lowering overall usage costs. Even under extreme heat, the film maintains a long-lasting, like-new shine, eliminating the need for frequent cleaning or replacement. It is easy to install and remove, allowing the film to be peeled off entirely from the car's surface, ensuring convenient and efficient operation for vehicle owners. Low Surface Energy Synergistic Bonding Technology: The crosslink density and uniformity of the coating are precisely optimized and combined with low-surface-energy materials to deliver exceptional resistance to contaminants, significantly extending the lifespan of the paint protection film. Coating–TPU Integration Layer: A unique process allows the coating's molecular chains to penetrate deeply into the TPU film, forming a robust integration layer. This effectively eliminates the peeling issues common with traditional protective films while further enhancing corrosion resistance. During the production process, the use of volatile organic compounds (VOCs) is significantly reduced. A small amount of exhaust gas is treated in a regenerative thermal oxidizer (RTO) and converted into carbon dioxide and water.

Credits

Entrant Company

WANDA COMMERCIAL PLANNING & RESEARCH INSTITUTE Co.,LTD

Category

Architectural Design - Commercial Building

Entrant Company

YuDian Design Co., Ltd

Category

Packaging Design - Herbal (NEW)

Entrant Company

Shenzhen Setinya Packaging Co., Ltd.

Category

Packaging Design - Snacks, Confectionary & Desserts

Entrant Company

Guangzhou Academy of Fine Arts

Category

Conceptual Design - Student Design