2025 | Professional

High-Accuracy SiC Device Reliability Test Platform

Entrant Company

Shenzhen Zhikai Boli Technology Co., LTD-Zhu Shudan

Category

Conceptual Design - Smart Technologies

Client's Name

Country / Region

China

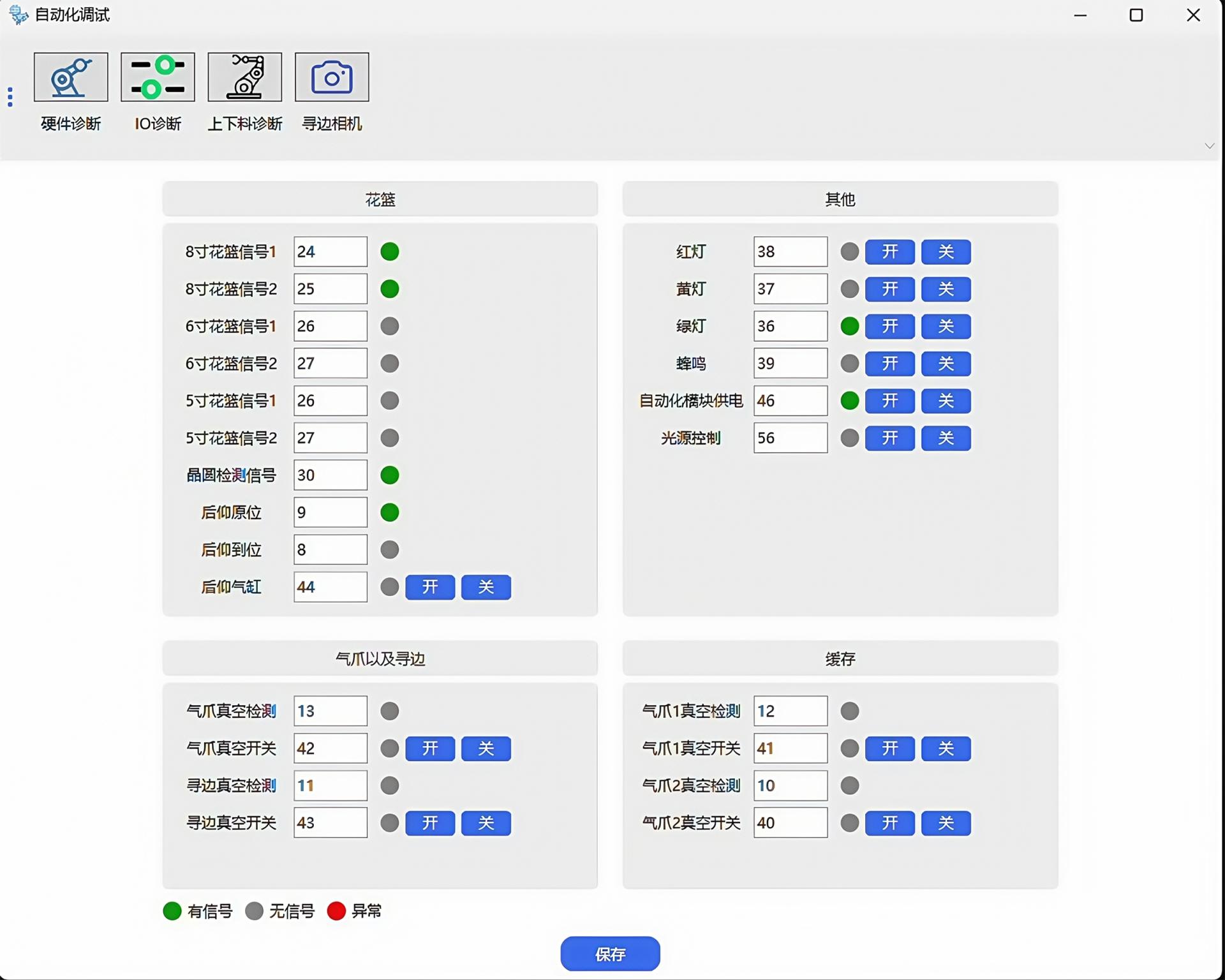

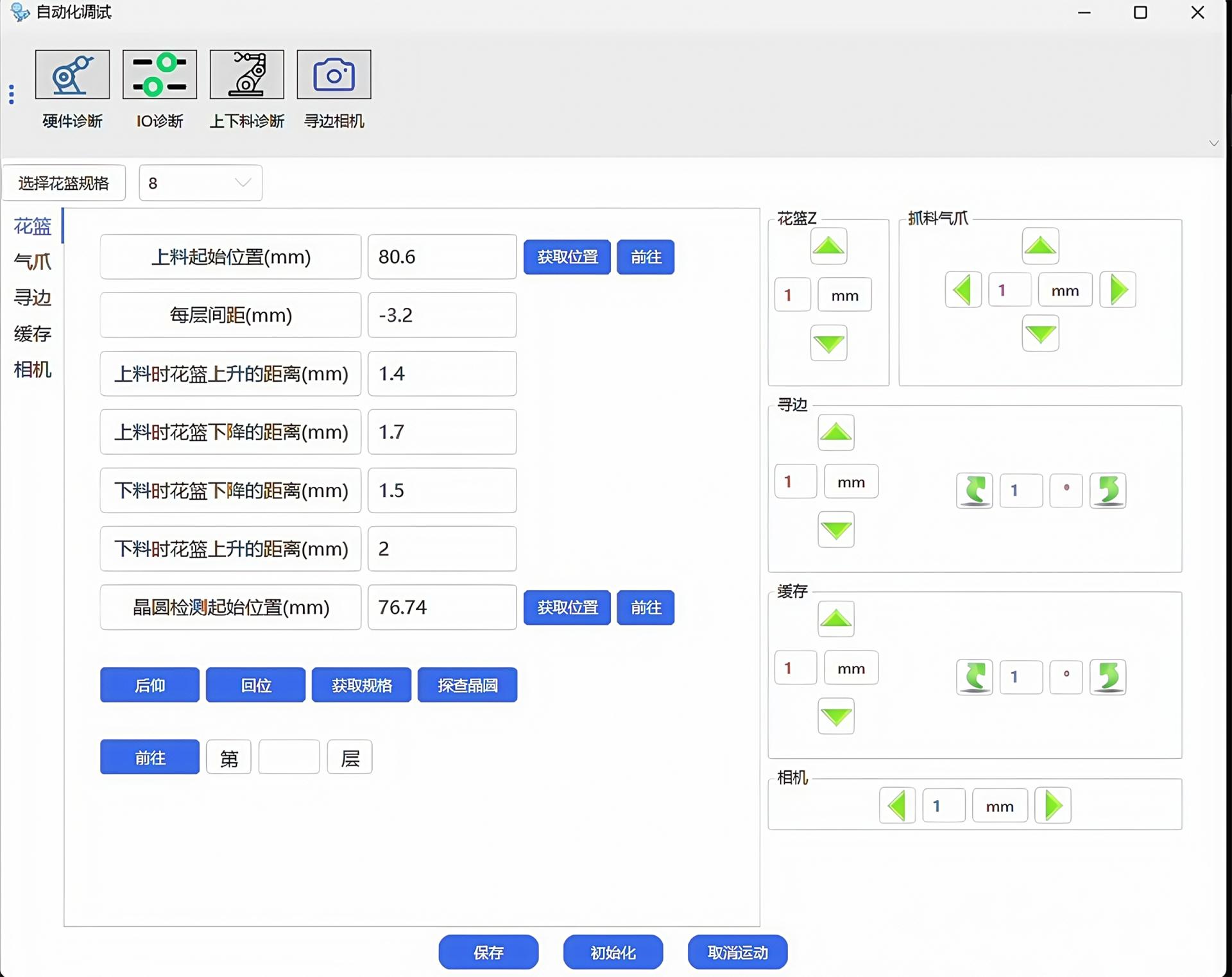

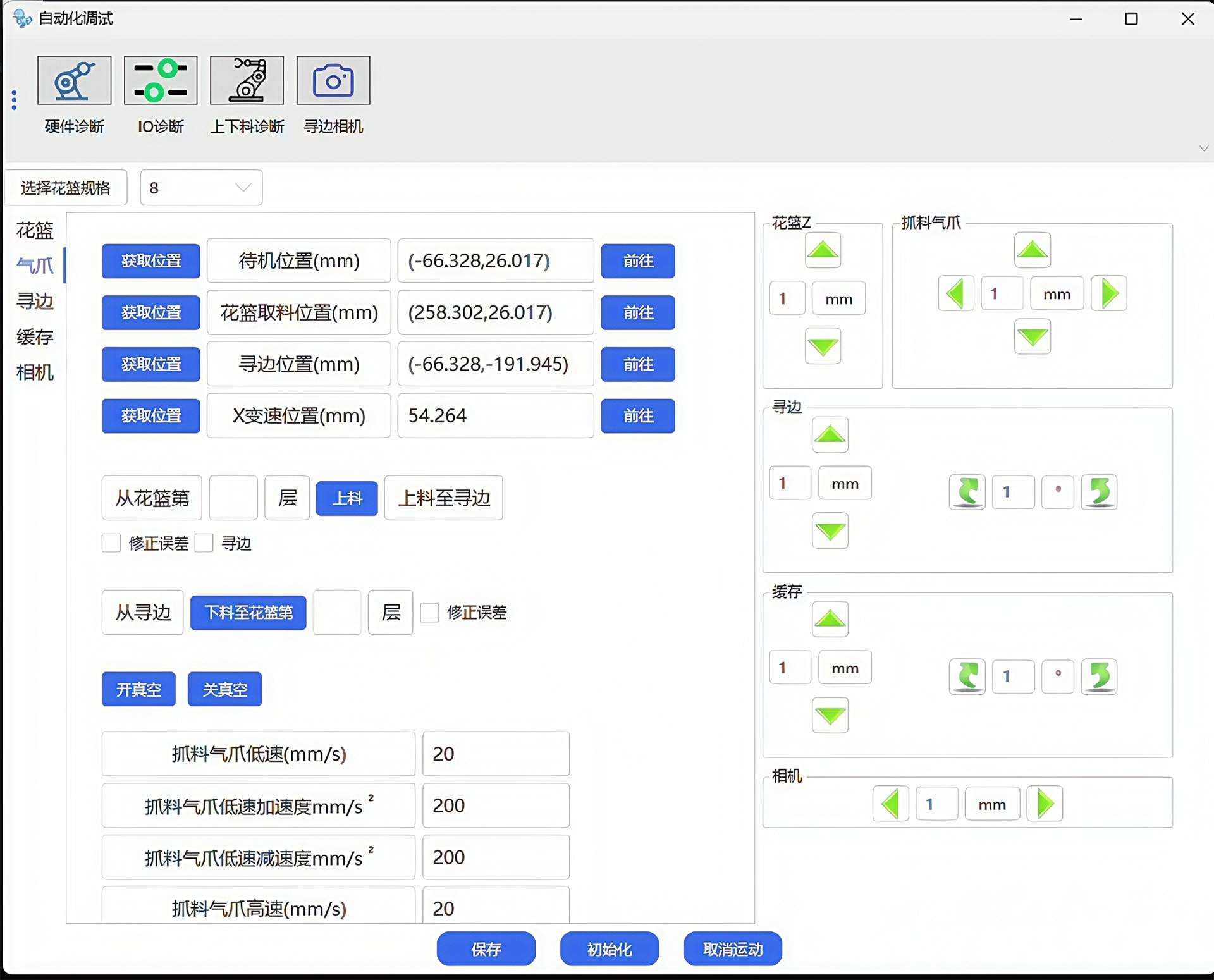

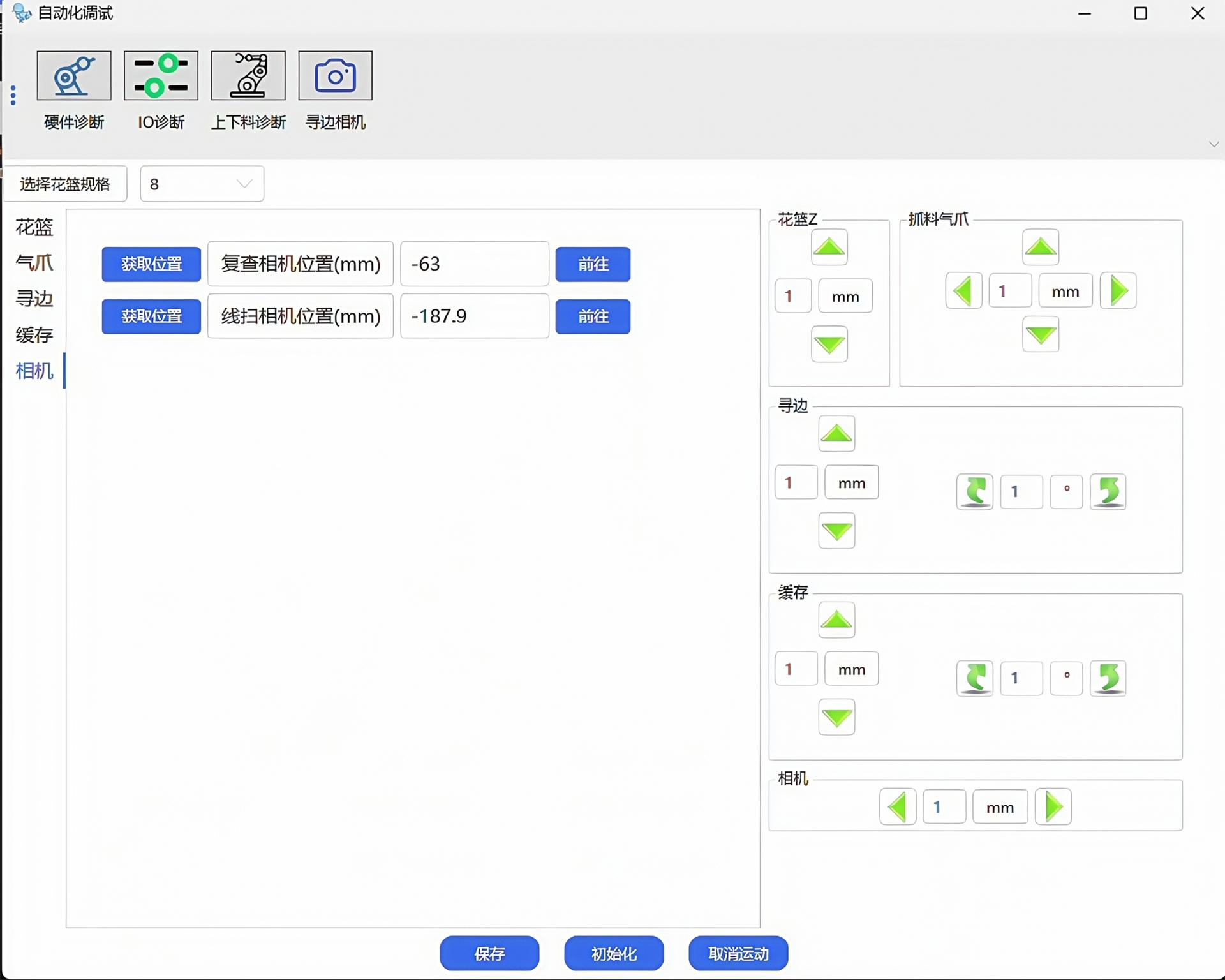

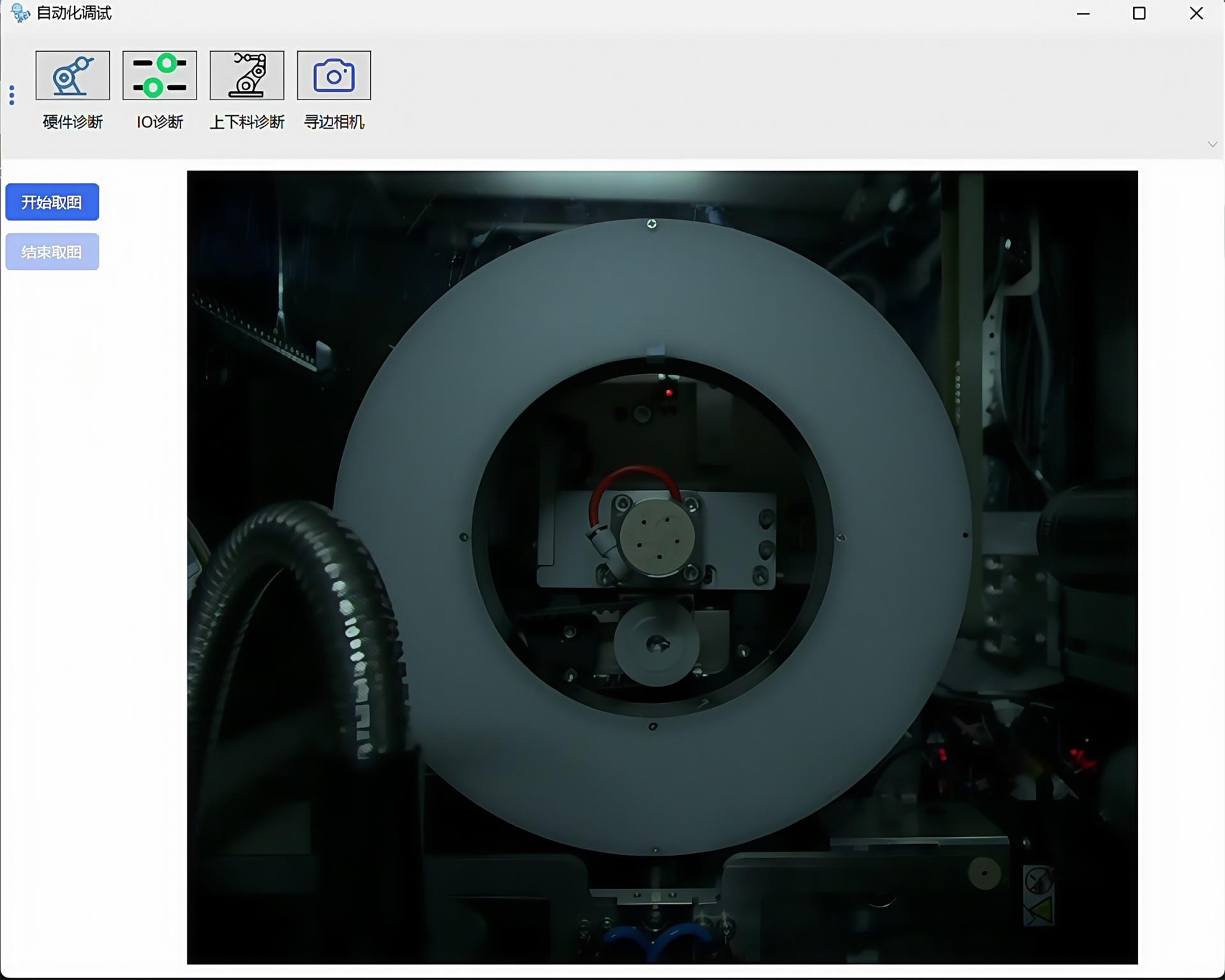

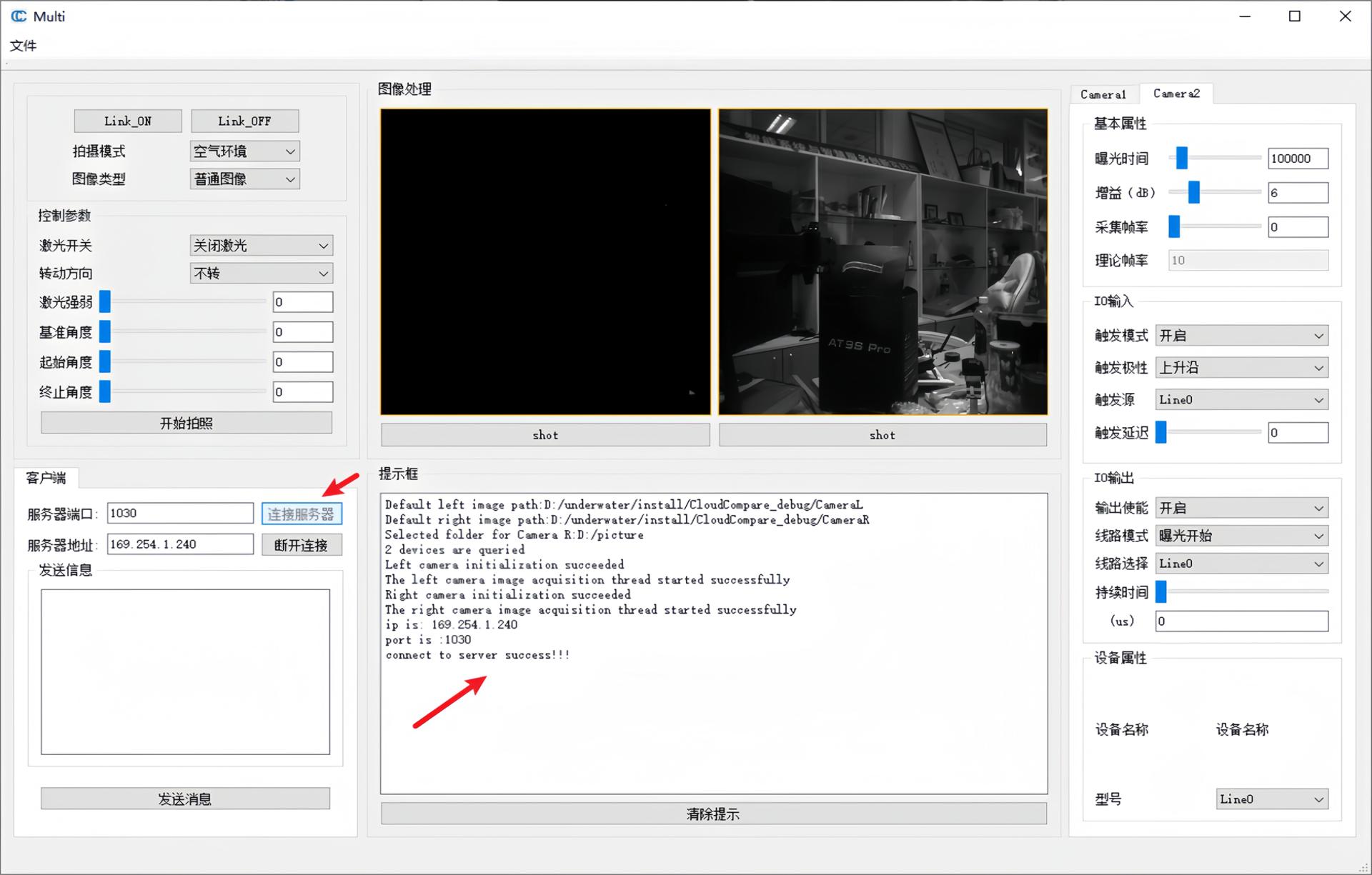

By integrating high-precision parameter measurement units, automated loading and unloading systems, intelligent error correction algorithms, and end-to-end data management software, the High-Precision Reliability Integrated Test Platform for Silicon Carbide (SiC) Power Devices enables integrated testing of the static parameters, dynamic characteristics, and reliability indicators of SiC power devices at the wafer-level, package-level, and system-level. Meanwhile, leveraging the Inversion of Control (IoC) and Dependency Injection (DI) architecture, the platform allows flexible expansion of hardware adaptation scope. By virtue of real-time data monitoring, camera positioning compensation, and abnormal response strategies, it ensures high repeatability precision of the testing process and equipment safety.

In response to the challenges in SiC device testing—including high precision requirements (e.g., ultra-low loop stray inductance must be less than 10nH), complex reliability evaluation (needing to comply with dynamic HTGB, HTRB, and other automotive-grade standards), and prominent efficiency bottlenecks—the platform offers an integrated solution. Previously, traditional testing methods had obvious drawbacks: static DC stress testing could not simulate actual switching conditions and resulted in significant dispersion in test data; furthermore, the loading and unloading process was prone to introducing errors, and there existed relatively high wafer safety risks.

To address these issues, the platform significantly increases test throughput (e.g., dynamic testing efficiency reaches 300 UPH) through automated loading/unloading interfaces, intelligent error correction methods such as visual positioning, and an integrated design for dynamic and static testing. It also controls parameter measurement accuracy to the level of pA-grade resolution, while supporting high-voltage testing conditions ranging from -100V to 2000V—meeting the requirements of automotive-grade standards including AQG324.

With the adoption of this platform, the testing consistency of SiC devices in the R&D and mass production phases, as well as the efficiency of early failure screening, have been significantly improved. The measurement deviation of dynamic parameters has been greatly reduced, and the cost of wafer-level testing has been effectively controlled through pre-packaging screening.

In terms of testing efficiency, data traceability, system scalability, and wafer safety protection, this platform is significantly superior to traditional discrete testing equipment, representing the cutting-edge technological direction in the field of SiC device testing.

Credits

Entrant Company

Zhejiang FirstDot Design Consulting Co., Ltd.

Category

Packaging Design - Wine, Beer & Liquor

Entrant Company

Meng Zhao

Category

Architectural Design - Museum, Exhibits, Pavilions

Entrant Company

Vintage Zinc Interiors, LLC

Category

Interior Design - Lobby (NEW)

Entrant Company

Gao Zhenghua / Yu Dingzong / Liu Weiping

Category

Architectural Design - Cultural